The SAE100R2 / 2SN is a high-quality hydraulic rubber hose that complies with the SAE J517 standard and is designed for medium- and high-pressure hydraulic systems. Featuring a double-layer steel wire braid reinforcement, this hose offers excellent pressure resistance, pulse resistance, and flexibility, making it suitable for use in harsh environments such as construction machinery, agricultural equipment, and industrial hydraulic systems.

Key Features:

✅ Double-layer steel wire braid construction – Provides higher pressure and pulse resistance, suitable for dynamic hydraulic systems.

✅ Excellent oil resistance – The NBR inner tube is compatible with a variety of hydraulic fluids, ensuring long-term stable operation.

✅ Wear and aging resistance – The outer rubber layer is UV and ozone resistant, suitable for outdoor use and harsh conditions.

✅ Flexible and easy to install – Compared to more rigid hoses like 4SP/4SH, it is more suitable for applications requiring flexibility.

✅ International certifications – Complies with SAE, EN, and ISO standards, ensuring global compatibility.

SAE 100R2/EN 853 2SN hydraulic hose product specifications

Standards SAE J517 100R2 / EN 853 2SN

Inner Layer: Oil-resistant Nitrile Butadiene Rubber (NBR)

Reinforcement: Two layers of high-strength steel wire braid

Outer Layer: Abrasion-resistant and age-resistant synthetic rubber

ID: 3/16″-2"

Working Pressure: 8-41.5 MPa (6,000 psi)

Burst Pressure: 32 Mpa - 166 MPa (24,000 psi)

Temperature Range: -40°C to +100°C (temporarily up to +120°C)

Applicable Fluids: Mineral oil, bio-based hydraulic fluid, water glycol (HFA, HFB)

|

Part No. |

I.D. |

O.D. |

W.P |

B.P |

B.R |

W.T |

|||

|

Dash |

Inch |

mm |

mm |

MPa |

PSI |

MPa |

PSI |

mm |

kg/m |

|

2SN-03 |

3/16″ |

4.8 |

13.4 |

41.5 |

6018 |

166 |

24070 |

90 |

0.320 |

|

2SN-04 |

1/4″ |

6.4 |

15.0 |

40.0 |

5800 |

160 |

23200 |

100 |

0.352 |

|

2SN-05 |

5/16″ |

7.9 |

16.5 |

35.0 |

5075 |

140 |

20300 |

115 |

0.443 |

|

2SN-06 |

3/8″ |

9.5 |

18.9 |

33.0 |

4785 |

132 |

19140 |

125 |

0.540 |

|

2SN-08 |

1/2″ |

12.7 |

22.2 |

27.5 |

3988 |

110 |

15950 |

180 |

0.680 |

|

2SN-10 |

5/8″ |

15.9 |

25.6 |

25.0 |

3625 |

100 |

14500 |

205 |

0.779 |

|

2SN-12 |

3/4″ |

19.1 |

29.3 |

21.5 |

3118 |

86 |

12470 |

240 |

0.941 |

|

2SN-16 |

1″ |

25.4 |

37.8 |

16.5 |

2393 |

66 |

9570 |

300 |

1.350 |

|

2SN-20 |

1.1/4″ |

31.8 |

44.3 |

12.5 |

1813 |

50 |

7250 |

420 |

2.100 |

|

2SN-24 |

1.1/2″ |

38.1 |

50.3 |

9.0 |

1305 |

36 |

5220 |

500 |

2.650 |

|

2SN-32 |

2″ |

50.8 |

63.8 |

8.0 |

1160 |

32 |

4640 |

630 |

3.400 |

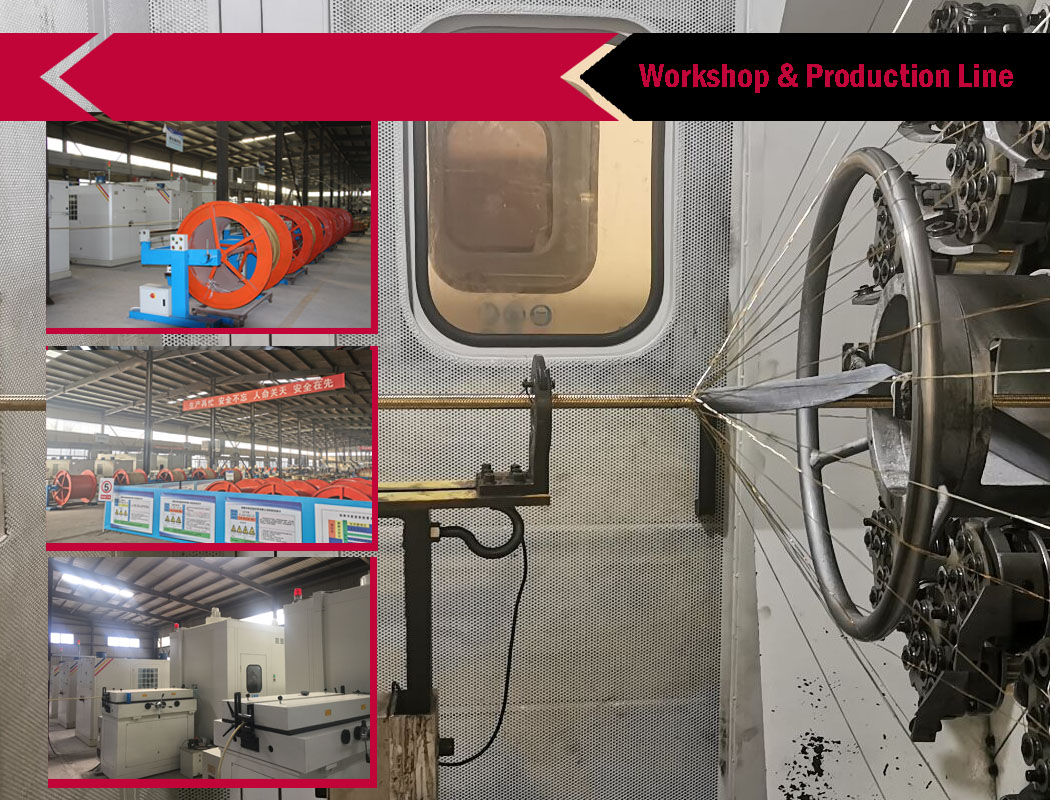

We changed steel wire joint machines to Germany ones, decreaing length tolerance about 50%.

New Germany Technology Braiding machines are 2-3 times quicker than old machines, and braiding wire cover more properly.

For rubber mixture and rolling, we biuld new workwhop of Auto Computer Control Rubber Mixture Center, which can make weight scale tolerance only 0.02 Gram for raw materials. For advanced technology of auto control in time and temperature, the center keep working state stably. It make all material uniform distributed , so that the rubber compound functions and performace can be used fully. For extruding machines, we also improve the line up to auto system, testing diameters by laser machine, to assure the diameters more accurate than SAE and EN 853 standards.

After finishing the production , we test every roll hose prove pressure in 1.8 times of working pressure to avoid any leakage.

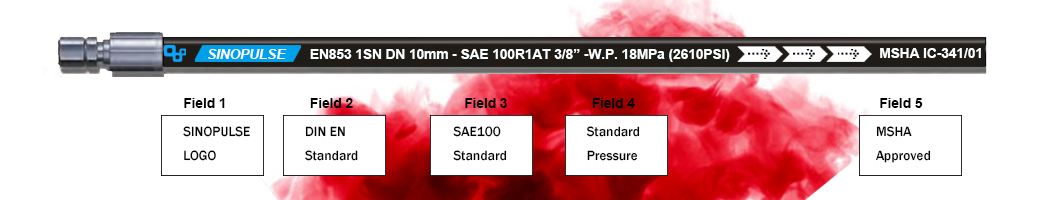

In any quality problem, we can trace back on ID card, which records all informaitons, showing which worker make it ? on which date, and by which mahince?

For improvment on quality and producution capacity, we can provide better service in lower prices and higher quality.

Application:

Suitable for conveyor low/medium pressure of oil/water based hydraulic fluids.

It can use with petroleum, synthetic or water based fluids in hydraulic systems for agricultural, earth moving, material handling equipment and systems.

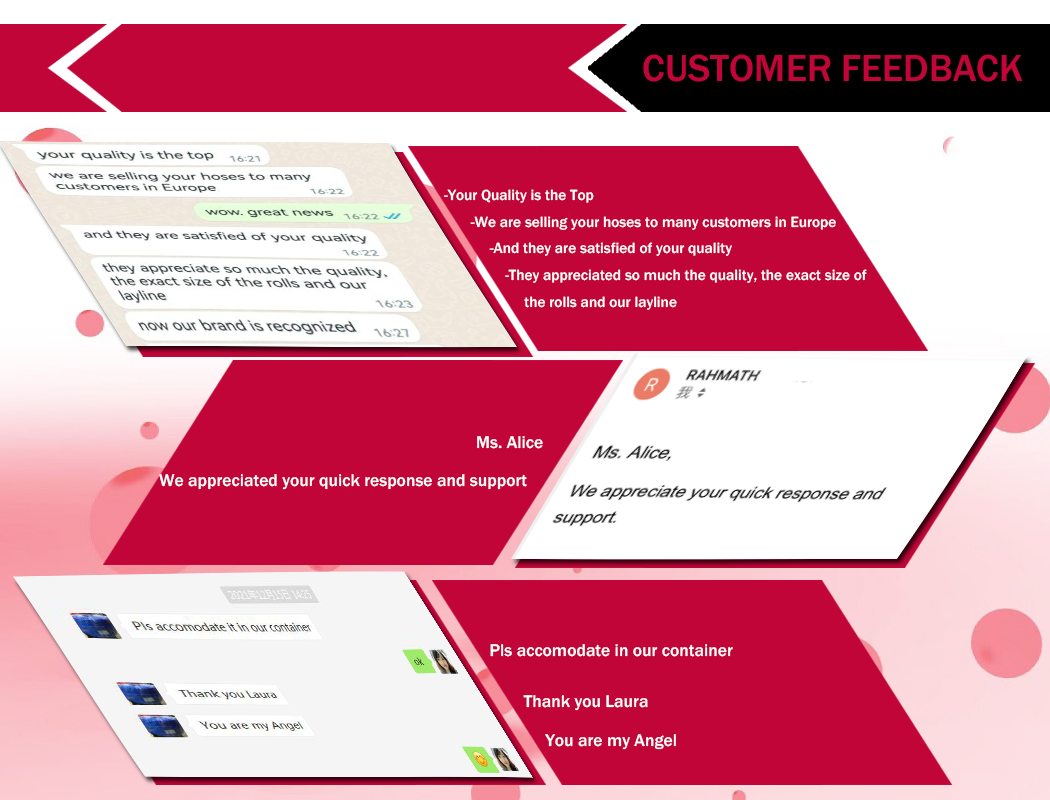

Our Company:

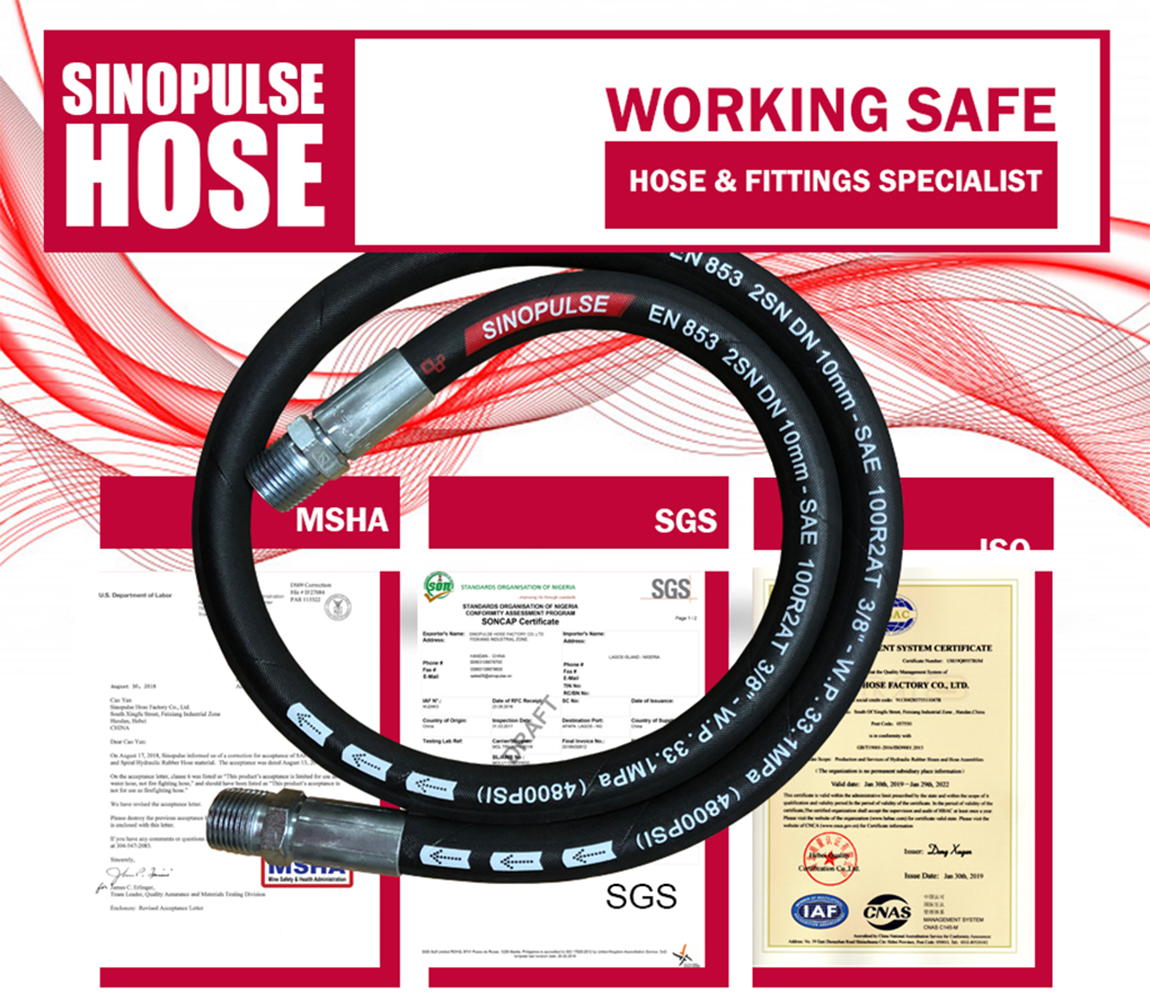

Sinopulse is a market-leading hydraulic hose factory and a professional trading company.

We manufacture hydraulic hoses that can deliver high pressure hydraulic fluids and stand the hardest working environment. Our hoses can perform well in both high and low and pressures, and also suitable for a variety of applications.

All of our hydraulic hose are in compliance with stringent industry standards such as SAE 100 and DIN. We also have MSHA and ISO certificates.

Our hydraulic hoses can fit in a wide variety of adapters and fittings.

They are designed for being used with petroleum and water-based hydraulic fluids.

They can handle gasoline, diesel fuel, mineral oil, lubricating oil, etc.

Hydraulic hose can handle high pressures in many fluid-power applications, like agricultural and manufacturing engineering, and other heavy equipment operations.

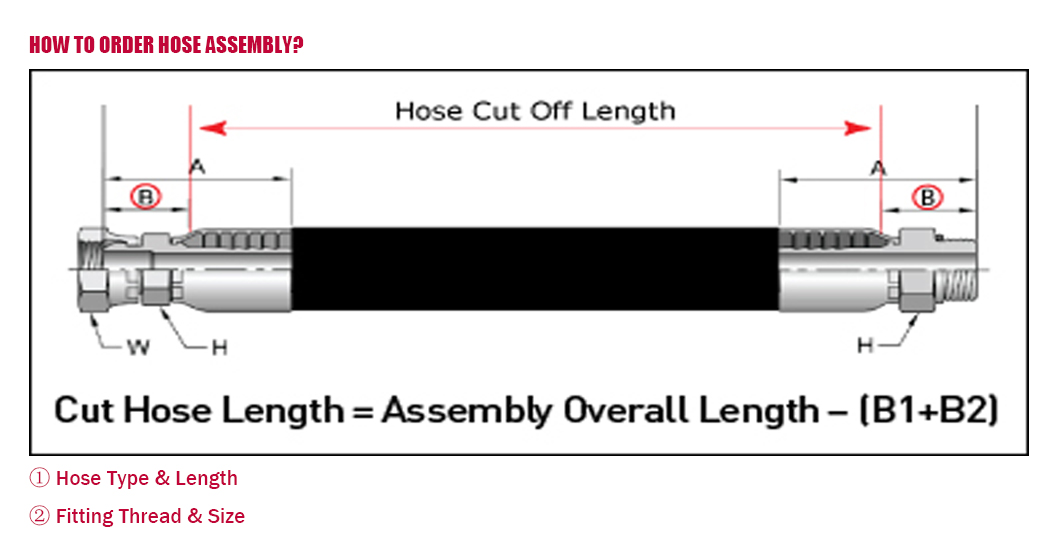

We also support making hydraulic assemblies for our customers.

The assembly is hydraulic hose with crimp fittings pre-attached.

Customization of the hose type, length,and fittings, creates the perfect product for your project.

We have a large hydraulic hose range, which can satisfy your different applications.

SAE100 R1AT/EN 853 1SN (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R2AT/EN853 2SN (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

DIN 20023/EN 856 4SP (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

DIN 20023/EN 856 4SH (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R12 (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R13 (FOUR OR SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R15 (SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

EN 857 1SC (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

EN857 2SC (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R16 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R17 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R3 / EN 854 2TE (TWO FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R6 / EN 854 1TE (ONE FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R5 (FIBER BRAIDED COVER HYDRAULIC HOSE)

SAE100 R4 (HYDRAULIC OIL SUCTION HOSE)

SAE100 R14 (PTFE SS304 BRAIDED)

SAE100 R7 (ONE WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

SAE100 R8 (TWO WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)