Kita ngganti mesin sambungan kabel baja menyang Jerman, nyuda toleransi dawa udakara 50%.

Mesin Braiding Teknologi Jerman Anyar 2-3 kaping luwih cepet tinimbang mesin lawas, lan nutupi kabel braiding luwih bener.

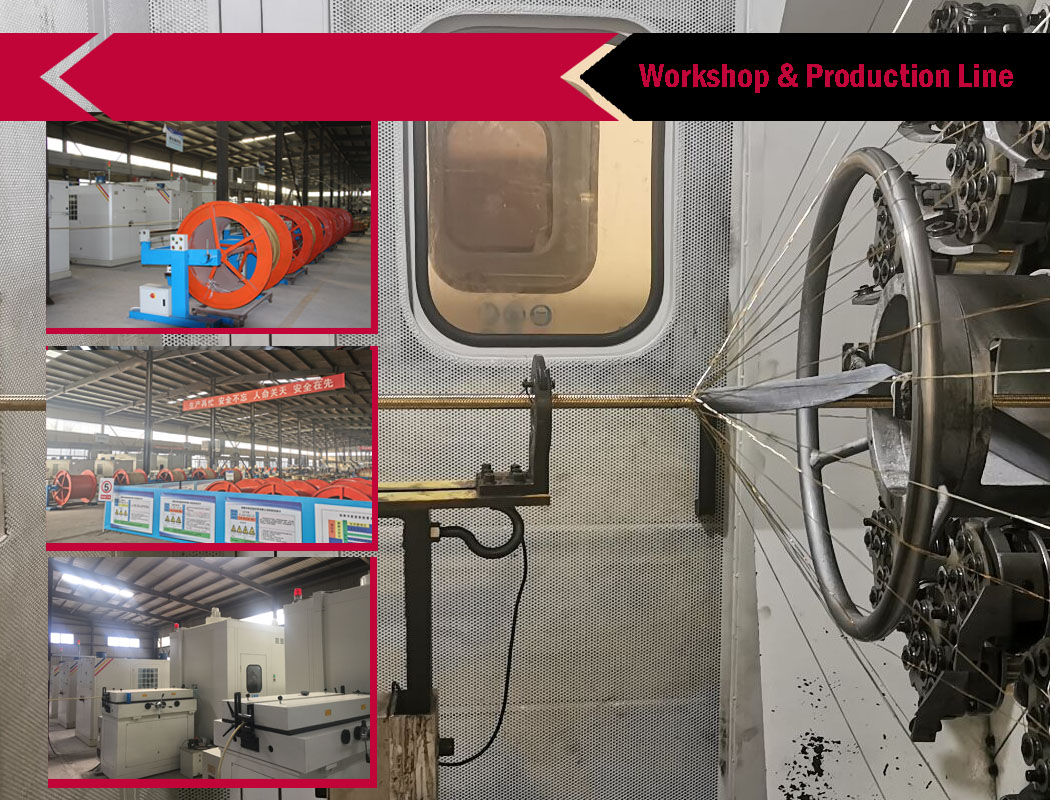

Kanggo campuran karet lan rolling, kita nggawe workwhop anyar Auto Computer Control Rubber Mixture Center, sing bisa nggawe toleransi ukuran bobot mung 0,02 Gram kanggo bahan mentah. Kanggo teknologi majeng kontrol otomatis ing wektu lan suhu, tengah tetep digunakake negara stably. Iku nggawe kabeh materi seragam mbagekke, supaya karet senyawa fungsi lan performace bisa digunakake kanthi. Kanggo mesin extruding, kita uga nambah garis nganti sistem otomatis, nguji diameter kanthi mesin laser, kanggo njamin diameter luwih akurat tinimbang standar SAE lan EN 853.

Sawise rampung produksi, kita nyoba saben selang gulung mbuktekake tekanan ing 1.8 kaping tekanan kerja supaya ora bocor.

Ing sembarang masalah kualitas, kita bisa nglacak bali ing KTP, kang ngrekam kabeh informaitons, nuduhake kang buruh nggawe? ing kang tanggal, lan dening kang mahince?

Kanggo nambah kualitas lan kapasitas produksi, kita bisa nyedhiyakake layanan sing luwih apik kanthi rega sing luwih murah lan kualitas sing luwih dhuwur.

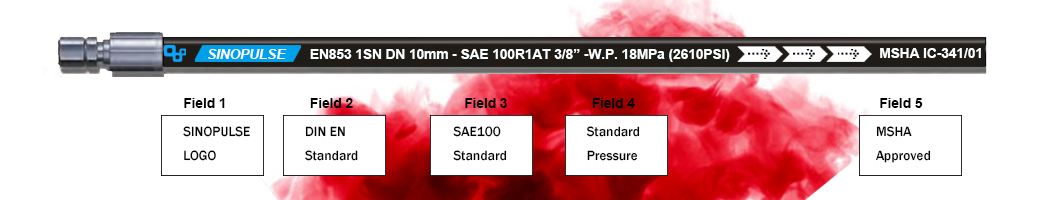

Fitur utama:

ngluwihi EN/DIN lan New SAE Tekanan kerja standar lan tekanan bursting

Properti tahan api saka tutup majemuk, MSHA 341/01 disetujoni

Tahan abrasion dhuwur, tahan tuwa, lan suhu dhuwur

merek OEM lan selang layline

|

Bagian No. |

ID |

OD |

WP |

BP |

BR |

WT |

|||

|

Dash |

inch |

mm |

mm |

MPa |

PSI |

MPa |

PSI |

mm |

kg/m |

|

2SN-03 |

3/16″ |

4.8 |

13.4 |

41.5 |

6018 |

166 |

24070 |

90 |

0.320 |

|

2SN-04 |

1/4″ |

6.4 |

15.0 |

40.0 |

5800 |

160 |

23200 |

100 |

0.352 |

|

2SN-05 |

5/16″ |

7.9 |

16.5 |

35.0 |

5075 |

140 |

20300 |

115 |

0.443 |

|

2SN-06 |

3/8″ |

9.5 |

18.9 |

33.0 |

4785 |

132 |

19140 |

125 |

0.540 |

|

2SN-08 |

1/2″ |

12.7 |

22.2 |

27.5 |

3988 |

110 |

15950 |

180 |

0.680 |

|

2SN-10 |

5/8″ |

15.9 |

25.6 |

25.0 |

3625 |

100 |

14500 |

205 |

0.779 |

|

2SN-12 |

3/4″ |

19.1 |

29.3 |

21.5 |

3118 |

86 |

12470 |

240 |

0.941 |

|

2SN-16 |

1″ |

25.4 |

37.8 |

16.5 |

2393 |

66 |

9570 |

300 |

1.350 |

|

2SN-20 |

1.1/4″ |

31.8 |

44.3 |

12.5 |

1813 |

50 |

7250 |

420 |

2.100 |

|

2SN-24 |

1.1/2″ |

38.1 |

50.3 |

9.0 |

1305 |

36 |

5220 |

500 |

2.650 |

|

2SN-32 |

2″ |

50.8 |

63.8 |

8.0 |

1160 |

32 |

4640 |

630 |

3.400 |

Aplikasi:

Cocog kanggo conveyor tekanan rendah / medium saka cairan hidrolik adhedhasar lenga / banyu.

Bisa digunakake karo petroleum, cairan sintetik utawa banyu adhedhasar sistem hidrolik kanggo tetanèn, obah bumi, peralatan lan sistem penanganan material.

Perusahaan kita:

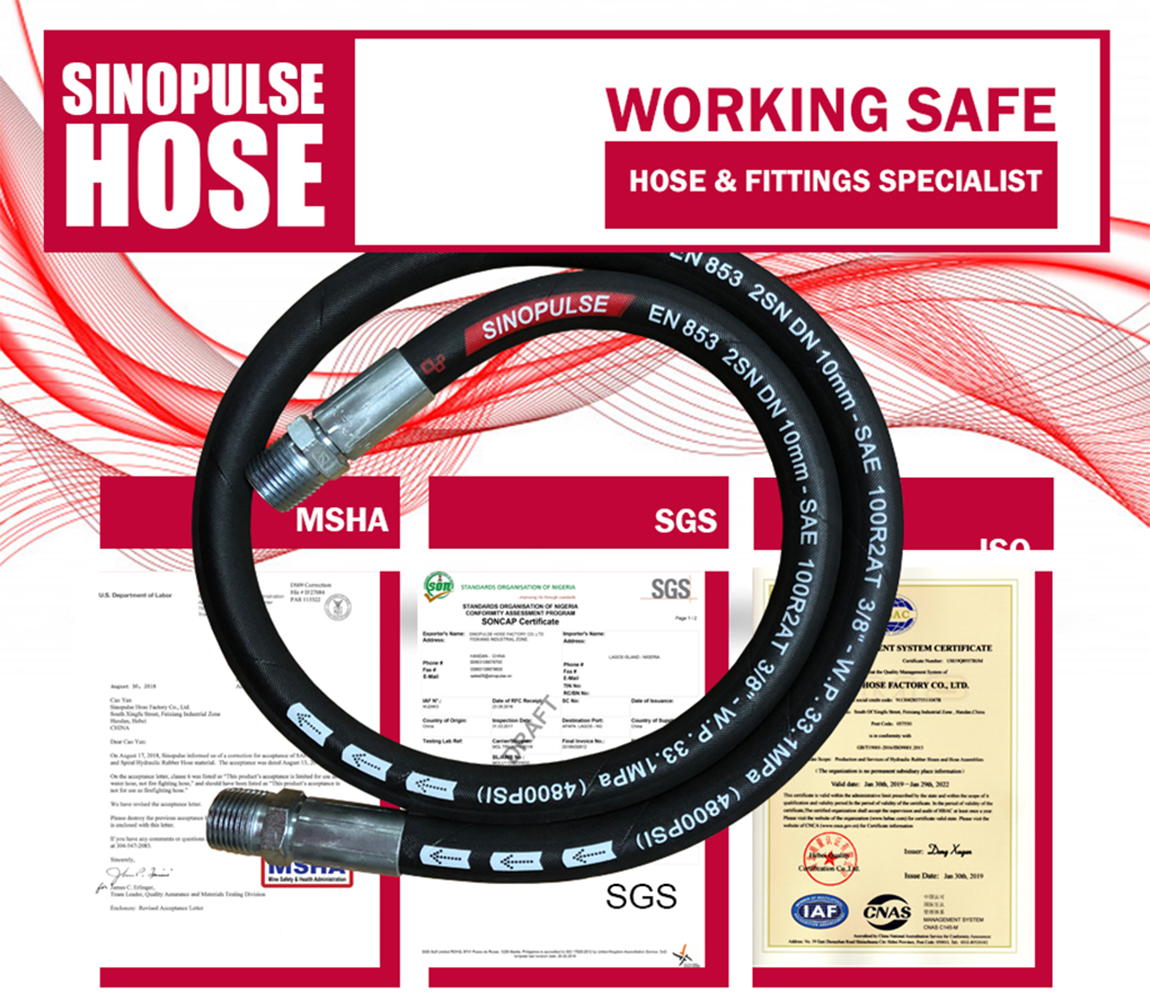

Sinopulse minangka selang hidrolik sing unggul ing pasar pabrik lan perusahaan dagang profesional.

We manufaktur hoses hydraulic sing bisa ngirim dhuwur tekanan fluida hidrolik lan ngadeg ing lingkungan kerja sing paling angel. Selang kita bisa nindakake uga in both high and low and pressures, lan ugi suitable for a variety of applications.

Kabeh saka selang hidrolik kita yaiku in compliance with stringent industry standards such as SAE 100 lan Saka. We uga duwe MSHA lan ISO sertifikats.

kita hidrolik hoses bisa pas ing macem-macem saka sudhut adaptor lan fitting.

Padha dirancang kanggo digunakake karo petroleum lan cairan hidrolik adhedhasar banyu.

padha can handle gasoline, diesel fuel, mineral oil, lubricating oil, lsp.

Selang hidrolik bisa nangani tekanan dhuwur ing akeh aplikasi daya cairan, kaya dheweke tanial lan manufaktur engineering, lan liyane heavy equipment operations.

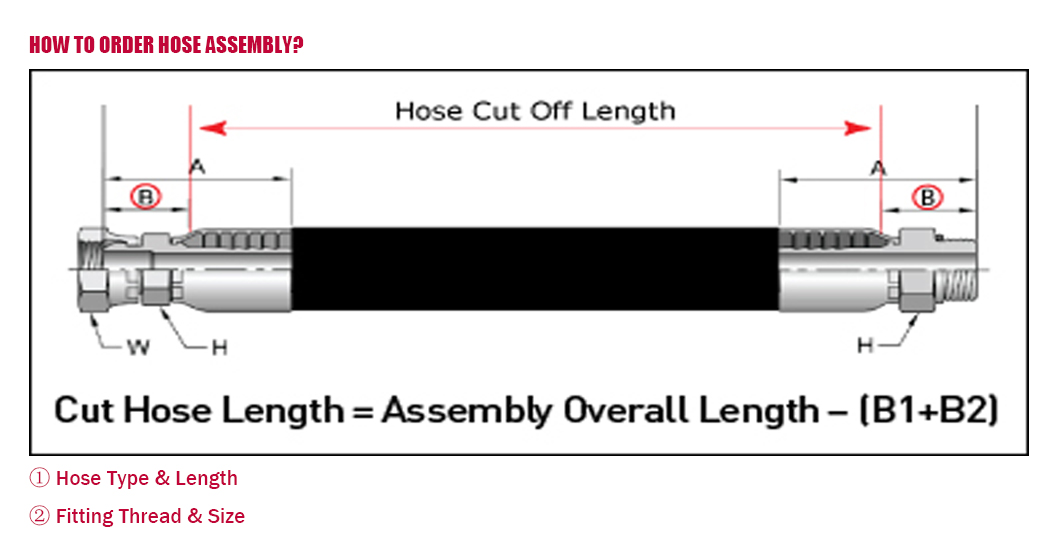

We uga ndhukung ibuing ngrakit hydraulicies kanggo kita pelanggan.

Ing ngumpuly iku selang hidrolik karo fitting crimp sing wis dipasang.

Customizasi saka the hose jinis, dawa, lan pass, nggawes sing sampurna produk kanggo proyek sampeyan.

Kita duwe sawetara selang hidrolik sing gedhe, sing bisa nyukupi macem-macem aplikasi sampeyan.

SAE100 R1AT/EN 853 1SN (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R2AT/EN853 2SN (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

DIN 20023/EN 856 4SP (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

DIN 20023/EN 856 4SH (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R12 (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R13 (FOUR OR SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R15 (SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

EN 857 1SC (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

EN857 2SC (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R16 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R17 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R3 / EN 854 2TE (TWO FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R6 / EN 854 1TE (ONE FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R5 (FIBER BRAIDED COVER HYDRAULIC HOSE)

SAE100 R4 (HYDRAULIC OIL SUCTION HOSE)

SAE100 R14 (PTFE SS304 BRAIDED)

SAE100 R7 (ONE WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

SAE100 R8 (TWO WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)