Fitur utama:

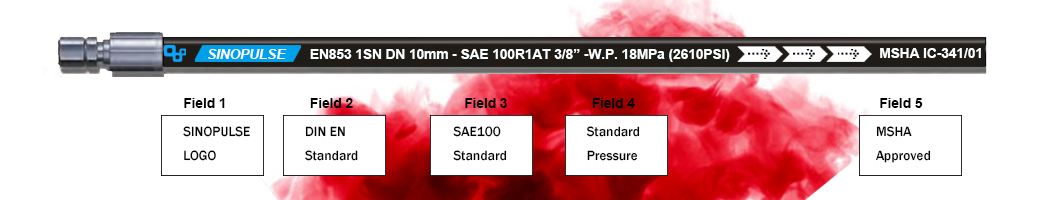

EN/DIN dan New SAE rated tekanan kerja

Cover flame resistant

Hydraulic hose R8

Layline disesuaikan

Alternative color: black, orange, yellow, blue,red

|

Bagian No. |

ID |

OD |

WP |

BP |

BR |

WT |

|||

|

Dash |

inch |

mm |

mm |

MPa |

PSI |

MPa |

PSI |

mm |

kg/m |

|

R8-02 |

1/8″ |

3.3 |

10.2 |

34.5 |

5003 |

138 |

20012 |

20 |

0.090 |

|

R8-03 |

3/16″ |

4.8 |

13.1 |

34.5 |

5003 |

138 |

20012 |

40 |

0.120 |

|

R8-04 |

1/4″ |

6.4 |

15.9 |

34.5 |

5003 |

138 |

20012 |

50 |

0.160 |

|

R8-05 |

5/16″ |

7.9 |

17.0 |

20.0 |

4350 |

120 |

17400 |

65 |

0.175 |

|

R8-06 |

3/8″ |

9.5 |

19.0 |

27.6 |

4002 |

110 |

16008 |

75 |

0.190 |

|

R8-08 |

1/2″ |

12.7 |

22.7 |

24.0 |

3480 |

95 |

13920 |

102 |

0.300 |

|

R8-10 |

5/8″ |

15.9 |

25.0 |

18.5 |

2683 |

74 |

10732 |

150 |

0.360 |

|

R8-12 |

3/4″ |

19.1 |

29.0 |

13.5 |

1958 |

54 |

7832 |

180 |

0.370 |

|

R8-16 |

1″ |

25.4 |

34.0 |

10.0 |

1450 |

40 |

5800 |

230 |

0.490 |

Aplikasi:

For use with petroleum, water and synthetic based fluids at medium pressure.

Iku is used in non-conductive applications where there are potential of contact with high voltage sources, such as blowout preventers, lube lines and construction machinery.

Perusahaan kita:

We are hydraulic hose manufacturer.

We pasokan hydraulic hoses that can work in the hardest working environment. Our hoses are designed to perform in both high and low and pressures and are suitable for a range of applications.

we have ISO lan MSHA sertifikat. Lan each saka selang hidrolik kita punika in compliance with stringent industry standards such as SAE 100 lan Saka.

Sinopulse is our registered brand, has sold to more than 30 domestic province and 60 cities. We also can offer the OEM service, the goods has been exported to USD, UK, Canada, Italy, Germany, Brazil, Russia……more than 40 countries.

Advanced technology, excellent quality and good reputation is the reason why our clients satisfied with our products. Now our company is expanding the scale of production, and welcome all the international friends visit our factory.

Kita duwe sawetara selang hidrolik sing gedhe, sing bisa nyukupi macem-macem aplikasi sampeyan.

SAE100 R1AT/EN 853 1SN (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R2AT/EN853 2SN (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

DIN 20023/EN 856 4SP (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

DIN 20023/EN 856 4SH (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R12 (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R13 (FOUR OR SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R15 (SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

EN 857 1SC (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

EN857 2SC (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R16 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R17 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R3 / EN 854 2TE (TWO FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R6 / EN 854 1TE (ONE FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R5 (FIBER BRAIDED COVER HYDRAULIC HOSE)

SAE100 R4 (HYDRAULIC OIL SUCTION HOSE)

SAE100 R14 (PTFE SS304 BRAIDED)

SAE100 R7 (ONE WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

SAE100 R8 (TWO WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

Three Lightweight Application Advantages 100 R8 Thermoplastic Hoses

As a leading thermoplastic hose manufacturer, SINOPULSE’s SAE 100 R8 hoses revolutionize industrial fluid transfer with their exceptional lightweight design. Engineered from advanced thermoplastic materials, these R8 hoses offer significant advantages over traditional rubber counterparts, optimizing performance in diverse applications.

Reduced Weight for Enhanced Mobility: Weighing up to 40% less than conventional rubber hoses, SAE 100 R8 thermoplastic hoses dramatically improve the mobility of equipment. In agricultural machinery, such as tractors and harvesters, the lighter hoses reduce the overall load, enhancing fuel efficiency and maneuverability. For example, a fleet of 50 tractors using R8 hoses could save up to 15% on fuel consumption annually, translating to substantial cost savings. In mobile construction equipment like excavators, the decreased weight eases the strain on hydraulic systems, reducing the risk of premature wear and tear. This not only extends component lifespan but also minimizes unplanned downtime, keeping projects on schedule.

Flexibility in Tight Spaces: The lightweight nature of R8 hoses doesn’t compromise flexibility. Their compact design allows for a smaller minimum bend radius—up to 30% less than standard rubber hoses—enabling seamless installation in confined spaces. In robotic arms and automated manufacturing lines, these hoses can navigate complex routes without kinking, ensuring smooth fluid flow and precise operation. The reduced bulk also simplifies routing in tight engine compartments of vehicles, where space is at a premium. This flexibility is particularly crucial in the aerospace industry, where every millimeter of space matters, and hoses must fit within intricate hydraulic systems without restricting movement.

Lower Installation and Transportation Costs: The lightweight profile of SINOPULSE SAE 100 R8 hoses translates to tangible cost savings. Easier handling during installation minimizes labor time by up to 20%, as workers can more quickly and efficiently route and connect the hoses. Moreover, the decreased weight reduces transportation costs for both raw materials and finished products. For large-scale infrastructure projects that require shipping thousands of hoses, these savings accumulate significantly, making R8 hoses a cost-effective choice for contractors and manufacturers. Additionally, the reduced weight eases the logistical burden, allowing for more efficient storage and handling throughout the supply chain.

In industries where weight, flexibility, and cost-efficiency matter, SINOPULSE’s SAE 100 R8 thermoplastic hoses stand out as the optimal solution. Contact us to explore how these lightweight hoses can transform your hydraulic system’s performance and deliver long-term value to your operations.

Four Technical Indicators SAE 100 R8 Hoses

As a trusted thermoplastic hose manufacturer, SINOPULSE understands that choosing the right SAE 100 R8 hose requires careful consideration of key technical parameters. These R8 thermoplastic hoses, prized for their lightweight design and durability, serve diverse industrial applications. Here are four critical indicators to guide your selection:

1. Pressure Rating and Burst Resistance

SAE 100 R8 hoses are engineered for medium to high-pressure hydraulic systems, with working pressures ranging from 1450 PSI to 5003 PSI, depending on the diameter. Their robust double-braided synthetic yarn reinforcement provides a safety factor of 4:1, ensuring burst pressures up to 20012 PSI. Matching the hose’s pressure rating to your system’s maximum operating pressure prevents leaks and failures, especially in demanding environments like construction machinery or mining equipment.

2. Temperature and Chemical Compatibility

Constructed from advanced thermoplastics, SINOPULSE R8 hoses maintain flexibility across a wide temperature range (-40°C to +93°C). The thermoplastic inner tube resists degradation from common hydraulic fluids, including mineral oils, water-glycol mixtures, and synthetic lubricants. For applications involving aggressive chemicals or extreme temperatures, verifying compatibility safeguards the hose’s integrity and extends its lifespan.

3. Bend Radius and Installation Flexibility

R8 hoses offer a minimum bend radius up to 30% smaller than traditional rubber hoses, enabling seamless routing in confined spaces. In robotic arms, aircraft hydraulic systems, or compact machinery, this flexibility reduces kinking risks and optimizes fluid flow. When selecting a hose, consider your equipment’s available installation space and movement requirements to ensure efficient operation.

4. Certification and Compliance

SINOPULSE’s SAE 100 R8 hoses meet international standards, including ISO 14024 and MSHA certification for flame resistance. These accreditations confirm the hose’s reliability in hazardous environments, such as oil rigs or underground mines. Prioritizing certified hoses ensures compliance with safety regulations and minimizes the risk of costly system failures.

By evaluating these technical indicators, you can confidently choose a SINOPULSE R8 thermoplastic hose that maximizes performance, durability, and safety in your hydraulic applications.