Key Features:

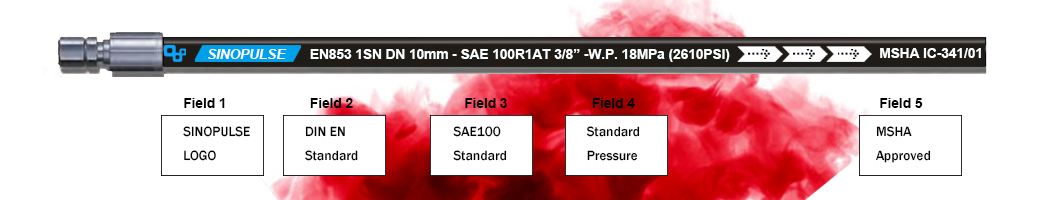

EN/DIN and New SAE rated working pressure

Cover flame resistant

Hydraulic hose R8

Layline customized

Alternative color: black, orange, yellow, blue,red

|

Part No. |

I.D. |

O.D. |

W.P |

B.P |

B.R |

W.T |

|||

|

Dash |

Inch |

mm |

mm |

MPa |

PSI |

MPa |

PSI |

mm |

kg/m |

|

R8-02 |

1/8″ |

3.3 |

10.2 |

34.5 |

5003 |

138 |

20012 |

20 |

0.090 |

|

R8-03 |

3/16″ |

4.8 |

13.1 |

34.5 |

5003 |

138 |

20012 |

40 |

0.120 |

|

R8-04 |

1/4″ |

6.4 |

15.9 |

34.5 |

5003 |

138 |

20012 |

50 |

0.160 |

|

R8-05 |

5/16″ |

7.9 |

17.0 |

20.0 |

4350 |

120 |

17400 |

65 |

0.175 |

|

R8-06 |

3/8″ |

9.5 |

19.0 |

27.6 |

4002 |

110 |

16008 |

75 |

0.190 |

|

R8-08 |

1/2″ |

12.7 |

22.7 |

24.0 |

3480 |

95 |

13920 |

102 |

0.300 |

|

R8-10 |

5/8″ |

15.9 |

25.0 |

18.5 |

2683 |

74 |

10732 |

150 |

0.360 |

|

R8-12 |

3/4″ |

19.1 |

29.0 |

13.5 |

1958 |

54 |

7832 |

180 |

0.370 |

|

R8-16 |

1″ |

25.4 |

34.0 |

10.0 |

1450 |

40 |

5800 |

230 |

0.490 |

Application:

For use with petroleum, water and synthetic based fluids at medium pressure.

It is used in non-conductive applications where there are potential of contact with high voltage sources, such as blowout preventers, lube lines and construction machinery.

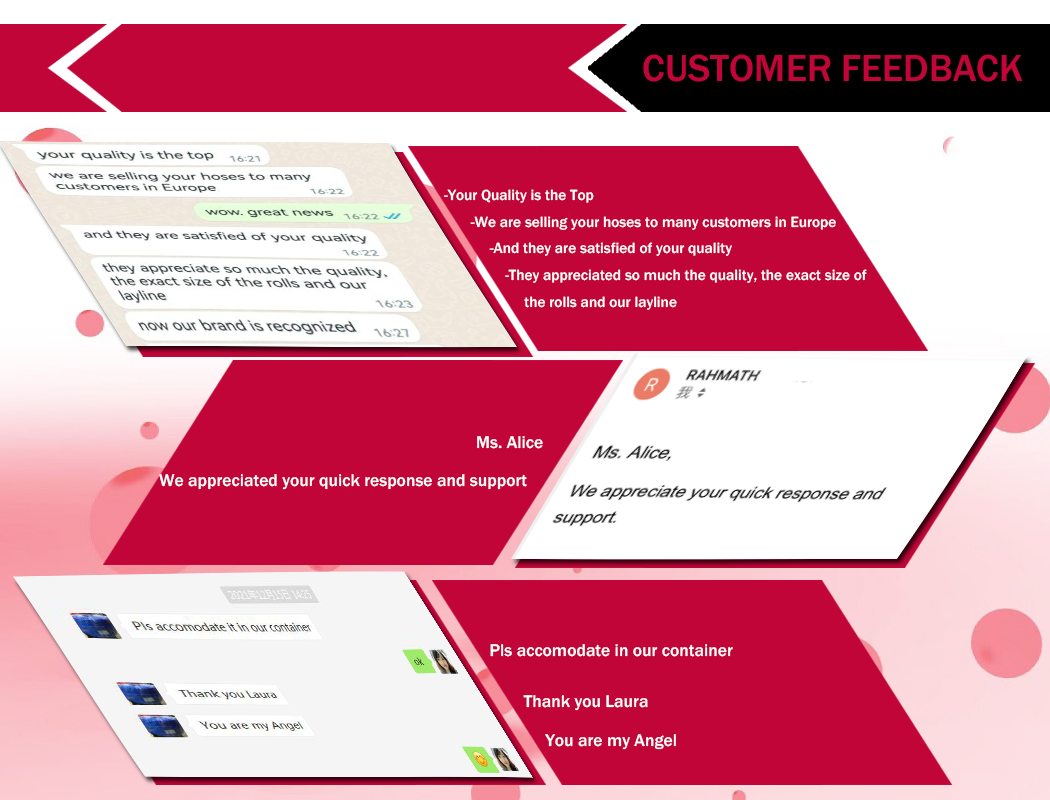

Our Company:

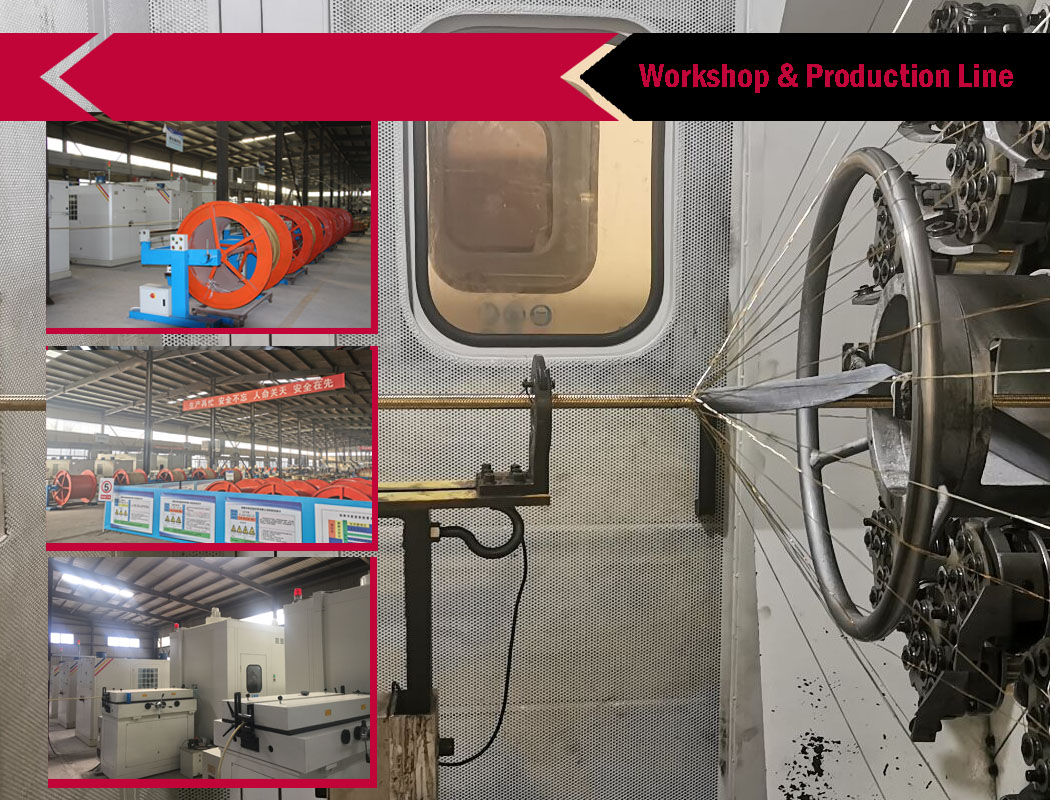

We are hydraulic hose manufacturer.

We supply hydraulic hoses that can work in the hardest working environment. Our hoses are designed to perform in both high and low and pressures and are suitable for a range of applications.

we have ISO and MSHA certificate. And each of our hydraulic hose is in compliance with stringent industry standards such as SAE 100 and DIN.

Sinopulse is our registered brand, has sold to more than 30 domestic province and 60 cities. We also can offer the OEM service, the goods has been exported to USD, UK, Canada, Italy, Germany, Brazil, Russia……more than 40 countries.

Advanced technology, excellent quality and good reputation is the reason why our clients satisfied with our products. Now our company is expanding the scale of production, and welcome all the international friends visit our factory.

We have a large hydraulic hose range, which can satisfy your different applications.

SAE100 R1AT/EN 853 1SN (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R2AT/EN853 2SN (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

DIN 20023/EN 856 4SP (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

DIN 20023/EN 856 4SH (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R12 (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R13 (FOUR OR SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R15 (SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

EN 857 1SC (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

EN857 2SC (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R16 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R17 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R3 / EN 854 2TE (TWO FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R6 / EN 854 1TE (ONE FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R5 (FIBER BRAIDED COVER HYDRAULIC HOSE)

SAE100 R4 (HYDRAULIC OIL SUCTION HOSE)

SAE100 R14 (PTFE SS304 BRAIDED)

SAE100 R7 (ONE WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

SAE100 R8 (TWO WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)