Fitur utama:

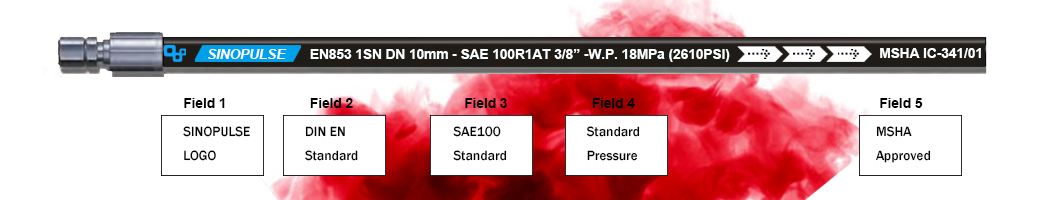

EN/DIN dan New SAE rated tekanan kerja

Properti tahan api saka kompoud tutup

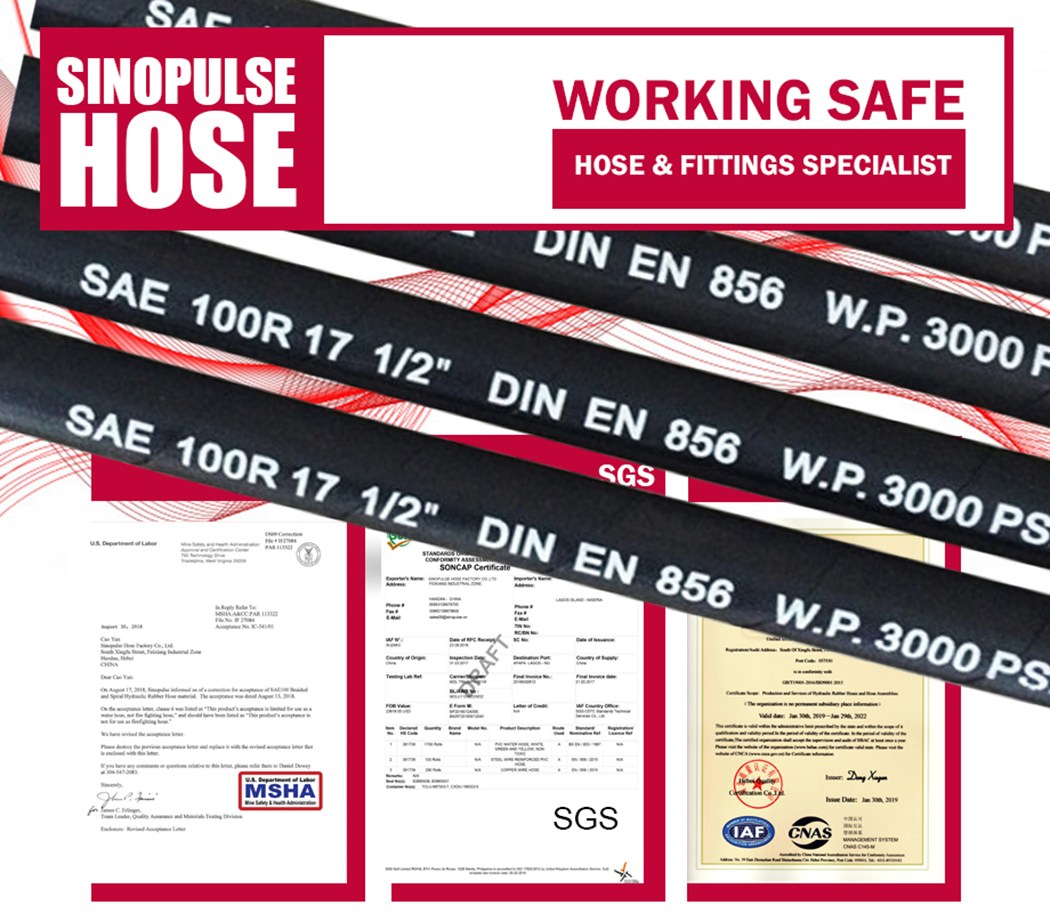

MSHA disetujoni

Gamelan covery FRAS disetujoni

Selang hidrolik R17

Brand selang layline OEM

|

Bagian No. |

ID |

OD |

WP |

BP |

BR |

WT |

|||

|

Dash |

inch |

mm |

mm |

MPa |

PSI |

MPa |

PSI |

mm |

kg/m |

|

R17-04 |

1/4″ |

6.4 |

13.2 |

21.0 |

3045 |

84 |

12180 |

50 |

0.200 |

|

R17-05 |

5/16″ |

7.9 |

15.0 |

21.0 |

3045 |

84 |

12180 |

55 |

0.230 |

|

R17-06 |

3/8″ |

9.5 |

17.0 |

21.0 |

3045 |

84 |

12180 |

65 |

0.290 |

|

R17-08 |

1/2″ |

12.7 |

21.1 |

21.0 |

3045 |

84 |

12180 |

90 |

0.380 |

|

R17-10 |

5/8″ |

15.9 |

25.9 |

21.0 |

3045 |

84 |

12180 |

100 |

0.640 |

|

R17-12 |

3/4″ |

19.1 |

30.3 |

21.0 |

3045 |

84 |

12180 |

120 |

0.800 |

|

R17-16 |

1″ |

25.4 |

38.6 |

21.0 |

3045 |

84 |

12180 |

150 |

1.280 |

Aplikasi hidrolik tekanan dhuwur lan kanggo ngganti R1 ing ngendi tekanan sing luwih dhuwur lan selang sing luwih fleksibel dibutuhake.

SAE 100R17 Selang karet hidraulik kompak nduweni radius tikungan sing luwih cilik lan becik kanggo rute sing ketat ing ngendi papan selang diwatesi. Iki nyedhiyakake tekanan kerja sing terus-terusan kanggo peralatan pertambangan, peralatan logging, penanganan material lan traktor pertanian.

Sinopulse minangka merek kadhaptar kita, wis didol ing udakara 60 negara. Kita melu manufaktur selang hidrolik, selang karet industri lan fitting selang ing China.

Pabrik kita didegaké ing taun 2001 wiwit nalika kita duwe pengalaman luwih saka 20 taun ing industri iki.

Produk kita lulus ISO9001: 2008 sertifikasi lan MSHA, ketemu standar internasional SAE J517 lan DIN EN. Kita uga surpport selang layline lan account selaras. OEM ditampa.

Teknologi canggih, kualitas apik, kontrol kualitas sing ketat, layanan profesional lan reputasi apik minangka alasan kenapa para klien puas karo tim kita.

Kita duwe sawetara selang hidrolik sing gedhe, sing bisa nyukupi macem-macem aplikasi sampeyan.

SAE100 R1AT/EN 853 1SN (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R2AT/EN853 2SN (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

DIN 20023/EN 856 4SP (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

DIN 20023/EN 856 4SH (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R12 (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R13 (FOUR OR SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R15 (SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

EN 857 1SC (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

EN857 2SC (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R16 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R17 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R3 / EN 854 2TE (TWO FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R6 / EN 854 1TE (ONE FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R5 (FIBER BRAIDED COVER HYDRAULIC HOSE)

SAE100 R4 (HYDRAULIC OIL SUCTION HOSE)

SAE100 R14 (PTFE SS304 BRAIDED)

SAE100 R7 (ONE WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

SAE100 R8 (TWO WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

Detailed Explanation of SAE 100 R17 Compact Wire Braided Hydraulic Hoses

As a leading hydraulic hose manufacturer, SINOPULSE delivers precision-engineered SAE 100 R17 hydraulic hoses designed for high-performance in space-constrained industrial applications. These compact hoses combine robust steel wire braiding with optimized dimensional specs, ensuring reliable pressure resistance and flexible installation. Below is a detailed breakdown of their technical parameters.

Pressure and Structural Specifications

SAE 100 R17 hoses are built to handle medium to high-pressure hydraulic systems, with working pressure ratings ranging from 207 bar (3000 PSI) for ¼" diameter models to 172 bar (2500 PSI) for 1" diameter variants. The burst pressure exceeds 621 bar (9000 PSI), providing a safety factor of 4:1, critical for preventing catastrophic failures in demanding environments like mining machinery or hydraulic presses. This strength comes from single or double layers of high-tensile steel wire braiding: smaller diameters (¼"–½") use a single braid, while larger sizes (⅝"–1") employ a double braid for enhanced reinforcement.

Dimensional and Flexibility Features

Available in diameters from ¼" to 1", these hoses feature a compact design that minimizes installation bulk. The minimum bend radius is optimized for tight spaces, ranging from 50 mm (2") for ¼" hoses to 150 mm (6") for 1" hoses—up to 30% smaller than standard hoses in similar pressure classes. This flexibility allows seamless routing in complex machinery, such as excavator arms or robotic hydraulic systems, without compromising flow efficiency. The outer layer, constructed from abrasion-resistant black synthetic rubber, offers protection against mechanical wear while maintaining flexibility for dynamic movements.

Temperature and Fluid Compatibility

SINOPULSE SAE 100 R17 hoses operate reliably across a wide thermal range, from -40°C (-40°F) in freezing industrial environments to +100°C (212°F) in moderate high-heat applications. The oil-resistant inner rubber layer is compatible with mineral-based hydraulic fluids, including petroleum oils, water-glycol emulsions, and biodegradable fluids, ensuring long-term resistance to swelling or degradation. Additionally, the hoses meet MSHA (Mine Safety and Health Administration) standards for flame resistance, making them suitable for use in hazardous mining and tunneling operations.

Quality and Certification Standards

Every hose undergoes rigorous testing to ensure compliance with SAE 100 R17 specifications, including:

Impulse Testing: at least 500,000 cycles at 1.5 times the working pressure to verify its fatigue resistance

Ozone Resistance: Exposure to 50 pphm ozone for 72 hours without cracking

Burst Pressure Testing: Conducted at 3x working pressure to verify safety margins

As a trusted manufacturer, SINOPULSE guarantees precision in every parameter, from wall thickness (ranging 2.0–4.0 mm) to overall diameter (9.5–28.5 mm), ensuring seamless integration with standard fittings like JIC 37°, BSPP, or NPT.

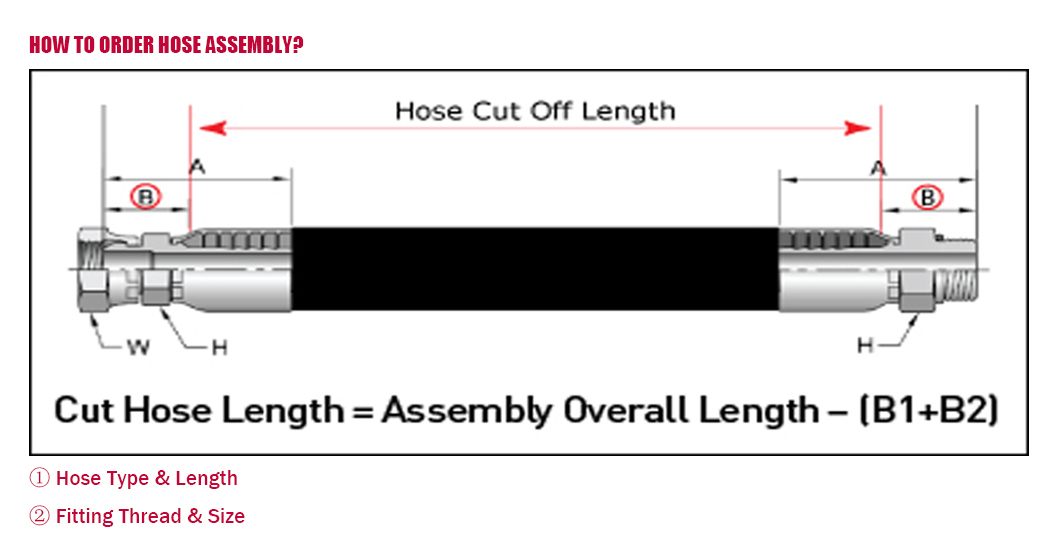

For custom configurations or detailed SAE 100 R17 hose specifications, contact our engineering team. We provide tailored solutions for length, end fittings, and marking requirements, ensuring your hydraulic system operates at peak performance.

SAE 100R16 usually adopts a double-layer steel wire braid structure, which is designed for higher working pressures and more severe working conditions, while R17 hydraulic hose is a lighter alternative with the same working pressure rating but allows the use of a single-layer steel wire braid structure. For large-diameter hoses, a double-layer steel wire braid structure can also be used to ensure pressure resistance.

In addition, SAE 100R17 hoses have smaller bending radius requirements, better flexibility and installation convenience, and are suitable for space-constrained equipment and mobile applications. Therefore, R17 can be used as a lightweight alternative to R16 on the premise of meeting pressure requirements.