Key Features:

Hydraulic hose 4SH

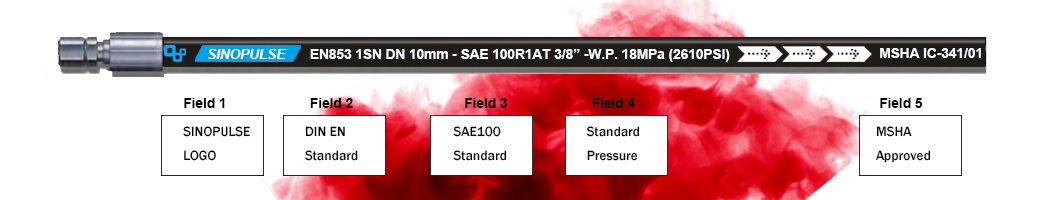

EN/DIN and New SAE rated working pressure

Flame resistant property of the cover compoud

High pressure rubber hose

OEM brand hose layline.

|

Part No. |

I.D. |

O.D. |

W.P |

B.P |

B.R |

W.T |

|||

|

Dash |

Inch |

mm |

mm |

MPa |

PSI |

MPa |

PSI |

mm |

kg/m |

|

4SH-12 |

3/4″ |

19.1 |

31.8 |

42.0 |

6090 |

168 |

24360 |

280 |

1.476 |

|

4SH-16 |

1″ |

25.4 |

38.7 |

38.0 |

5510 |

152 |

22040 |

340 |

1.984 |

|

4SH-20 |

1.1/4″ |

31.8 |

46.2 |

32.5 |

4713 |

130 |

18850 |

460 |

2.428 |

|

4SH-24 |

1.1/2″ |

38.1 |

53.5 |

29.0 |

4205 |

116 |

16820 |

560 |

2.871 |

|

4SH-32 |

2″ |

50.8 |

68.0 |

25.0 |

3625 |

100 |

14500 |

700 |

4.534 |

Application:

Very high pressure applications used for petroleum based hydraulic fluids.

With extraordinary flexibility, excellent bend radius properties and exceptional impulse life, it can be used in petroleum-based hydraulic fluids of very high pressure and tight bends.

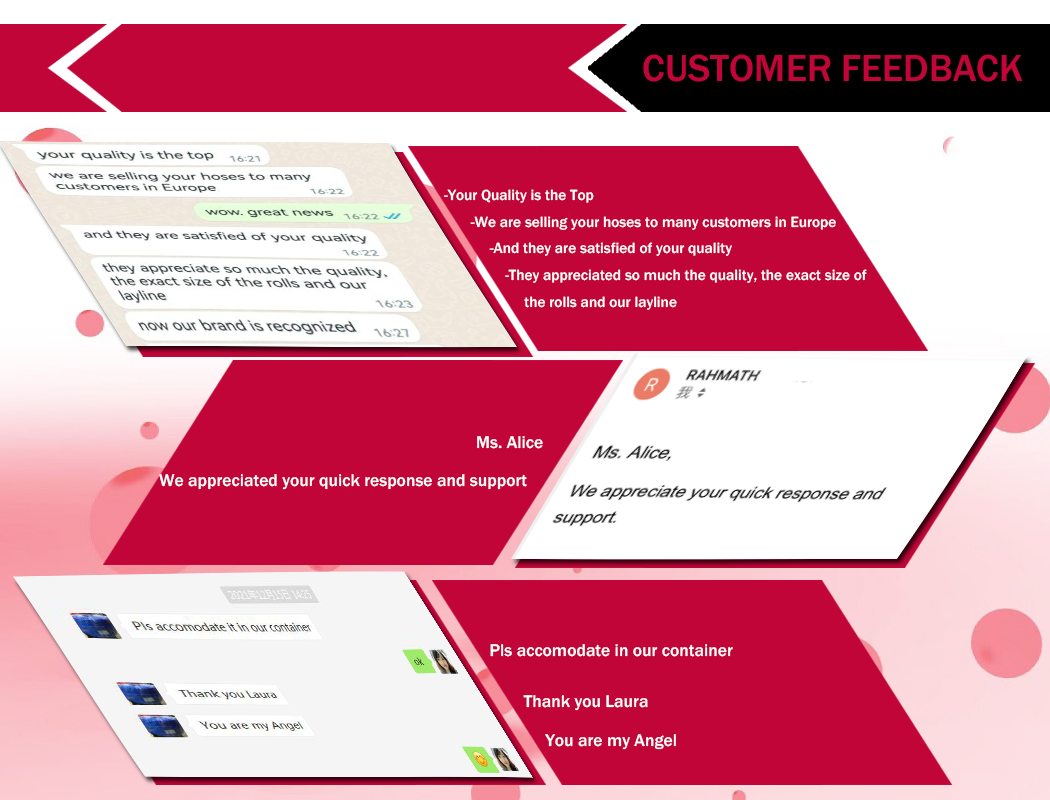

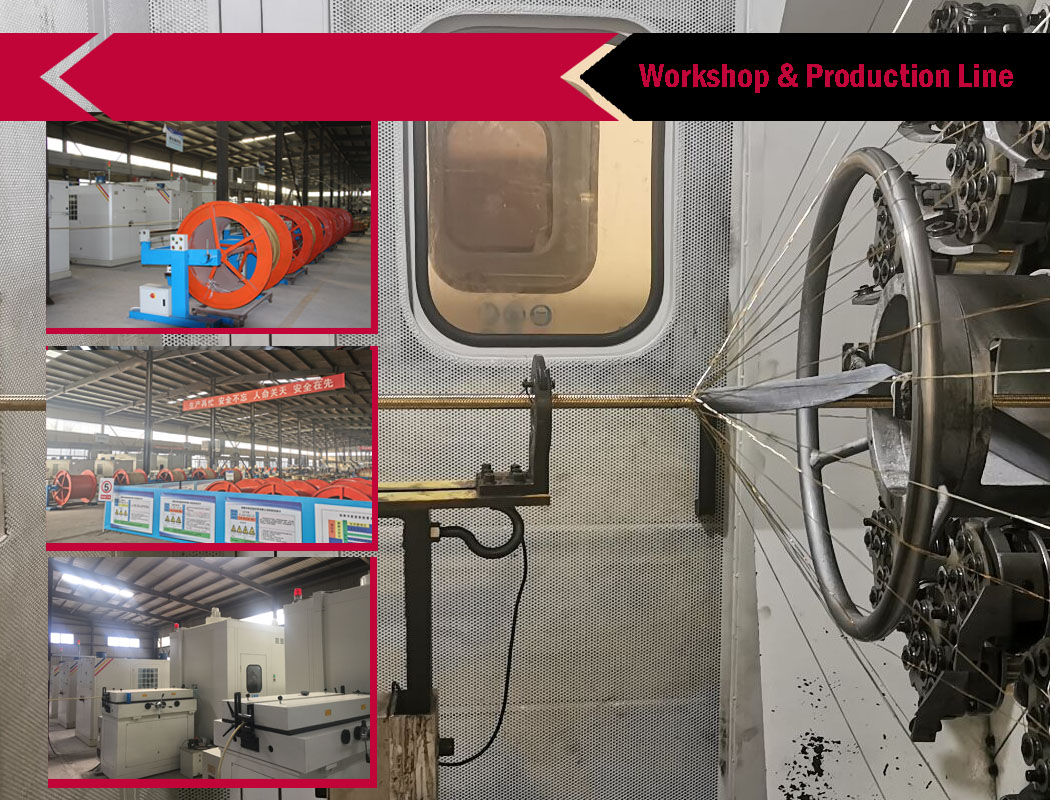

Our Company:

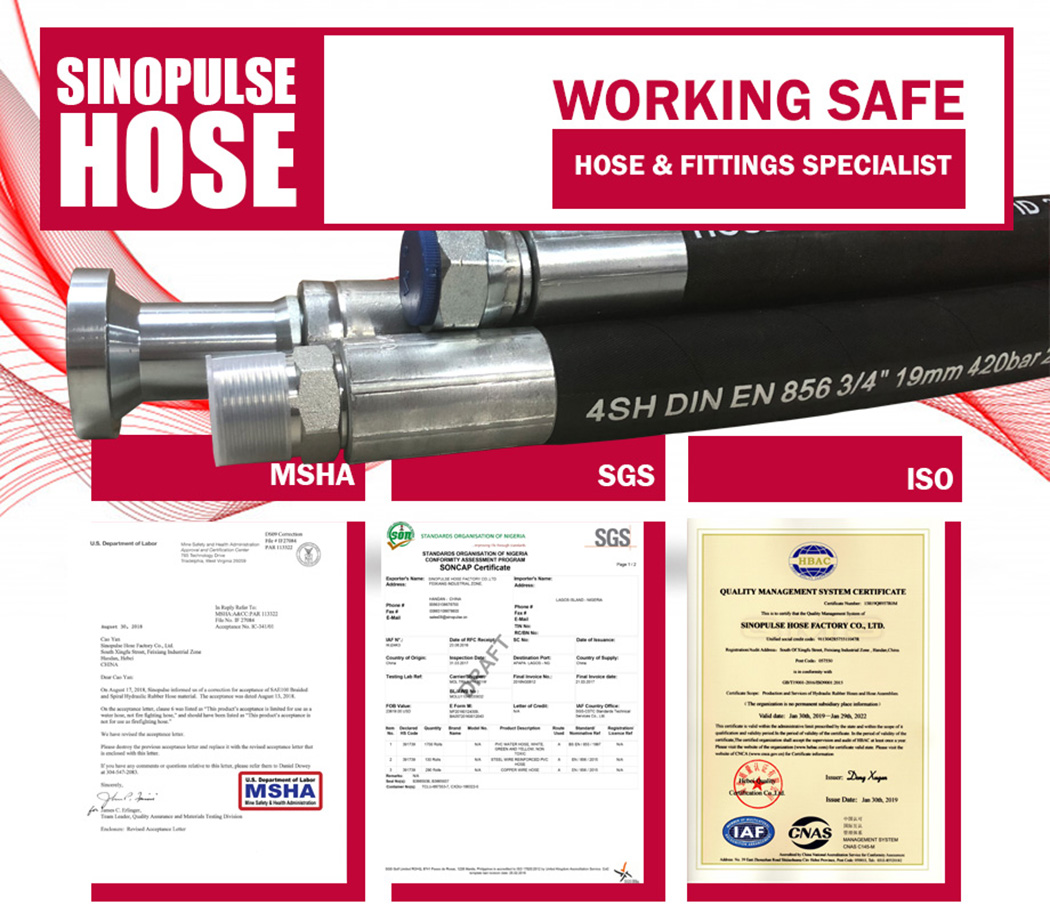

Sinopulse is a market-leading hydraulic hose manufacturer located in Handan, Hebei, China.

We supply hydraulic hoses that can deliver high pressure fluids and stand the hardest working environments. Our factory has very strict quality control, our workers take care from every step. So high quality is assured.

Each of our hydraulic hose is in compliance with stringent industry standards such as SAE 100 and DIN. We also have MSHA and ISO certificates.

Our reinforced hoses can fit in a lot of adapters and fittings.

Hydraulic hose is used with petroleum- and water-based hydraulic fluids. It can handle gasoline, diesel fuels, mineral oils, lubricating oils and so on.

Hydraulic hoses handle high pressure in a wide range of fluid-power applications, from agriculture and manufacturing, as well as heavy equipment operations.

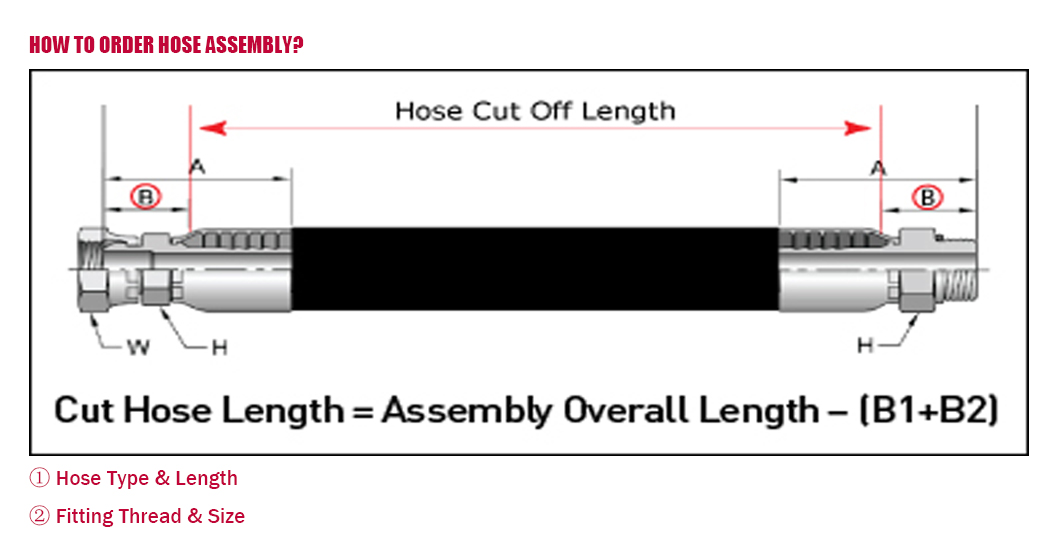

We can also make hydraulic assembly for our customers if they require. The finished assemblies are lengths of hydraulic hose with pre-attached crimp fittings. We support customizing the type of hose, length,and fitting to create the perfect assembly for your project.

Our full products range for Hydraulic Hose, based on Standard SAEJ517 and DIN EN

SAE100 R1AT/EN 853 1SN (3/16”,1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”, 1”, 1.1/4”, 1.1/2”, 2” )

SAE100 R2AT/EN853 2SN (3/16”,1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”, 1”, 1.1/4”, 1.1/2”, 2”)

DIN 20023/EN 856 4SP ( 3/8”, 1/2”, 5/8”, 3/4”, 1”, 1.1/4”, 1.1/2”, 2”)

DIN 20023/EN 856 4SH ( 3/4”, 1”, 1.1/4”, 1.1/2”, 2”)

SAE100 R12 (3/8”, 1/2”, 5/8”, 3/4”, 1”, 1.1/4”, 1.1/2”, 2”)

SAE100 R13 ( 3/4”, 1”, 1.1/4”, 1.1/2”, 2”)

SAE100 R15 (3/4”, 1”, 1.1/4”, 1.1/2”, 2”)

EN 857 1SC (3/16”,1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”, 1”)

EN857 2SC (3/16”,1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”, 1”)

SAE100 R16 (3/16”,1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”, 1”)

SAE100 R17 (3/16”,1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”, 1”)

SAE100 R3 / EN 854 2TE (3/16”,1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”, 1”, 1.1/4”, 1.1/2”, 2”)

SAE100 R6 / EN 854 1TE (3/16”,1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”, 1”, 1.1/4”, 1.1/2”, 2”)

SAE100 R5 (3/16”,1/4”, 5/16”, 3/8”, 13/32”,1/2”, 5/8”, 7/8” ,3/4”, 1.1/8”, 1.3/8”)

SAE100 R4 (3/8”, 1/2”, 5/8”, 3/4”, 1”, 1.1/4”, 1.3/4”,1.1/2”, 2”, 2.1/2”, 3”, 3.1/2”, 4” )

SAE100 R14 (1/8”,3/16”,1/4”, 5/16”, 3/8”, 13/32”,1/2”, 5/8”, 7/8” ,3/4”,1” )

SAE100 R7 (1/8”,3/16”,1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”, 1”)

SAE100 R8 (1/8”,3/16”,1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”, 1”)