Hauptmerkmale:

Hydraulikschlauch R14

EN/DIN und neuer SAE-Nennbetriebsdruck

Flammhemmende Eigenschaft der Abdeckmasse

MSHA und ISO-Zertifikat

Glatte Abdeckung FRAS-geprüft

Schlauch-Layline der OEM-Marke

|

Teile-Nr. |

AUSWEIS |

OD |

WP |

Blutdruck |

BR |

Gewicht |

|||

|

Bindestrich |

Zoll |

mm |

mm |

MPa |

PSI |

MPa |

PSI |

mm |

mm |

|

R14-02 |

1/8″ |

3.5 |

6.6 |

32.6 |

4727 |

97.8 |

14181 |

51 |

1.00 |

|

R14-03 |

3/16″ |

4.8 |

8.0 |

24.7 |

3582 |

74.1 |

10745 |

75 |

0.85 |

|

R14-04 |

1/4″ |

6.3 |

9.2 |

21.4 |

3103 |

64.2 |

9309 |

81 |

0.85 |

|

R14-05 |

5/16″ |

7.9 |

11.0 |

19.1 |

2770 |

57.3 |

8309 |

92 |

0.85 |

|

R14-06 |

3/8″ |

9.7 |

12.8 |

18.8 |

2726 |

56.4 |

8178 |

131 |

0.85 |

|

R14-08 |

1/2″ |

12.7 |

15.9 |

10.8 |

1566 |

32.4 |

4698 |

182 |

1.00 |

|

R14-10 |

5/8″ |

15.8 |

19.2 |

12.9 |

1871 |

38.7 |

5612 |

211 |

1.00 |

|

R14-12 |

3/4″ |

19.0 |

22.7 |

7.9 |

1146 |

23.7 |

3437 |

338 |

1.20 |

|

R14-14 |

7/8″ |

22.3 |

26.0 |

6.1 |

885 |

18.3 |

2654 |

421 |

1.20 |

|

R14-16 |

1″ |

25.4 |

29.3 |

4.8 |

696 |

14.4 |

2088 |

539 |

1.50 |

Anwendung:

Zum Transportieren von Hydraulikflüssigkeiten auf Chemikalien- und Erdölbasis.

SAE 100 R14 hydraulic hose is suitable for delivering petroleum or water-based hydraulic fluids in the working temperature of -54 °C to +204 °C. This kind of hose can be divided into two kinds according to the structure and material: type A and type B.

Type A is composed of tube and reinforcement. The tube is made from polytetrafluoroethylene (PTFE) and the reinforcement is made from one layer of 304 stainless steel.

Typ B ähnelt in seiner Struktur stark dem Typ A, verfügt jedoch über eine elektrisch leitfähige Innenfläche. Diese dient der Vermeidung elektrostatischer Aufladung.

Sinopulse ist ein marktführender Hersteller von Hydraulikschläuchen.

We offer hydraulic hoses that can deliver high performance and stand the hardest working environments. Our hoses are designed to perform in both high and low and pressures and are suitable for a variety of applications.

Jeder unserer Hydraulikschläuche entspricht strengen Industriestandards wie SAE 100 und DIN. Wir verfügen außerdem über ISO- und MSHA-Zertifikate.

Unsere Panzerschläuche passen auf eine Vielzahl von Adaptern und Armaturen.

Unser Hydraulikschlauch ist für den Einsatz mit Hydraulikflüssigkeiten auf Mineralöl- und Wasserbasis konzipiert. Er eignet sich für Benzin, Dieselkraftstoff, Mineralöle, Glykol, Schmieröle und mehr.

Hydraulikschläuche sind für den Umgang mit hohen Drücken in zahlreichen Hydraulikanwendungen geeignet, von der Landwirtschaft und Fertigung bis hin zum Einsatz von Schwermaschinen aller Art.

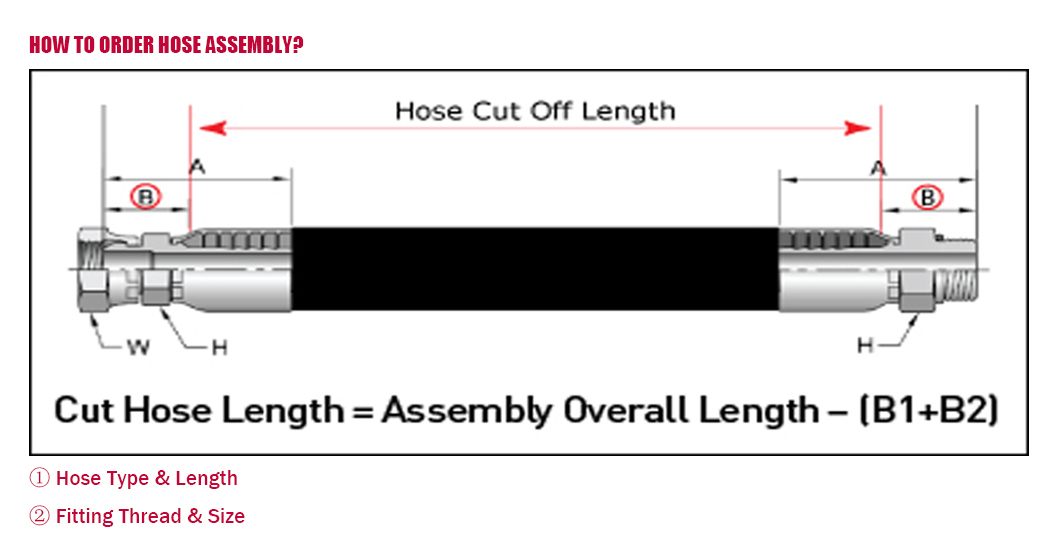

Wir fertigen auch Hydraulikbaugruppen für Kunden. Die fertigen Baugruppen bestehen aus Hydraulikschläuchen mit vormontierten Crimpverschraubungen. Passen Sie Schlauchtyp, Länge und Verschraubung individuell an, um die perfekte Baugruppe für Ihr Projekt zu erstellen.

Wir verfügen über ein großes Sortiment an Hydraulikschläuchen, die Ihren unterschiedlichen Anwendungen gerecht werden.

SAE100 R1AT/EN 853 1SN (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R2AT/EN853 2SN (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

DIN 20023/EN 856 4SP (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

DIN 20023/EN 856 4SH (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R12 (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R13 (FOUR OR SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R15 (SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

EN 857 1SC (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

EN857 2SC (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R16 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R17 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R3 / EN 854 2TE (TWO FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R6 / EN 854 1TE (ONE FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R5 (FIBER BRAIDED COVER HYDRAULIC HOSE)

SAE100 R4 (HYDRAULIC OIL SUCTION HOSE)

SAE100 R14 (PTFE SS304 BRAIDED)

SAE100 R7 (ONE WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

SAE100 R8 (TWO WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

Core Structure and Material of SAE 100 R14 PTFE Hoses

As a vanguard among PTFE hose manufacturers, SINOPULSE engineers SAE 100 R14 hoses with a meticulous blend of innovation and precision. These PTFE braided hoses, fortified with stainless steel reinforcement, represent the pinnacle of performance in extreme industrial conditions, serving critical applications in aerospace, chemical processing, semiconductor manufacturing, and beyond.

The inner tube of SINOPULSE SAE 100 R14 hoses is crafted from premium polytetrafluoroethylene (PTFE), a material celebrated for its exceptional chemical inertness and thermal resilience. PTFE’s molecular structure renders it impervious to degradation from concentrated acids, caustic alkalis, and aggressive petroleum-based fluids, ensuring seamless compatibility with a vast spectrum of media. This chemical resistance is particularly crucial in pharmaceutical and semiconductor industries, where contamination risks must be minimized. Additionally, PTFE’s non-stick surface reduces friction by up to 80% compared to traditional rubber hoses, optimizing fluid flow and preventing pressure drop even in high-viscosity applications. Its ability to maintain flexibility across a staggering -60°C to +260°C temperature range ensures consistent performance from cryogenic storage to high-heat industrial furnaces.

Overlaying the PTFE layer is a stainless steel braided reinforcement composed of 304-grade alloy, a cornerstone of the hose’s mechanical prowess. This braided structure distributes internal pressure evenly, enabling the hose to withstand working pressures up to 4727 PSI and burst pressures reaching 14181 PSI—a safety factor of nearly 3:1. In mining or oil extraction equipment, where hydraulic systems endure constant vibration and abrasive conditions, the stainless steel braid acts as a shield, protecting the PTFE core from external wear and tear. Moreover, the braid’s interwoven design allows for a minimum bend radius 25% smaller than conventional hoses, facilitating installation in tight spaces such as aircraft engine bays or robotic hydraulic arms.

Completing the hose’s tri-layer architecture is a heat-resistant polymer outer cover, engineered to combat environmental threats. This layer provides superior protection against UV radiation, ozone, and mechanical impacts, extending the hose’s service life by up to 30% in outdoor or high-movement applications. In chemical plants or marine installations, the outer cover’s resistance to weathering and corrosion ensures the hose maintains structural integrity over prolonged exposure to harsh elements.

Together, the PTFE inner tube, stainless steel braid, and protective outer cover of SINOPULSE PTFE stainless steel braided hoses form a resilient system that excels in transporting corrosive chemicals, high-purity fluids, and abrasive materials. Whether you require a standard PTFE hydraulic hose or a customized solution, SINOPULSE’s commitment to engineering excellence ensures reliable performance across the most demanding hydraulic systems.

Special Application Scenarios of Anti-static SAE 100 R14 (Type B)

As a leading PTFE hose manufacturer, SINOPULSE’s anti-static SAE 100 R14 (Type B) hoses redefine safety and reliability in high-risk environments. Engineered as PTFE braided hoses with stainless steel reinforcement, these specialized products are designed to prevent electrostatic discharge (ESD), making them indispensable for industries where sparks pose catastrophic risks.

Fuel Transfer Systems: In the aerospace and automotive sectors, transferring highly flammable fuels like jet fuel or gasoline generates static electricity. SINOPULSE’s Type B hoses mitigate this danger with a conductive PTFE inner layer that safely dissipates static charges. The stainless steel braid acts as a grounding path, ensuring any accumulated charge is immediately neutralized. This feature is crucial for aircraft refueling operations and fuel storage facilities, where even a tiny spark could trigger explosions.

Chemical Processing Plants: When handling volatile chemicals or solvents, anti-static protection is non-negotiable. SINOPULSE PTFE stainless steel braided hoses excel in these scenarios, combining chemical resistance with ESD prevention. The PTFE material resists degradation from aggressive substances, while the anti-static design safeguards against ignition sources. This dual functionality makes them ideal for transporting solvents in paint manufacturing or hazardous materials in petrochemical plants.

Pharmaceutical and Food Industries: In environments requiring strict safety and hygiene, static electricity can attract contaminants or interfere with precision equipment. SINOPULSE PTFE hydraulic hoses address these concerns by eliminating static buildup, ensuring product purity, and operational integrity. Whether used in pharmaceutical fluid transfer or food processing lines, the Type B hoses meet stringent industry standards, providing peace of mind for critical applications.

SINOPULSE’s anti-static SAE 100 R14 hoses offer a comprehensive solution for safety-sensitive industries. Contact us to explore how our engineered products can enhance the safety and efficiency of your operations.