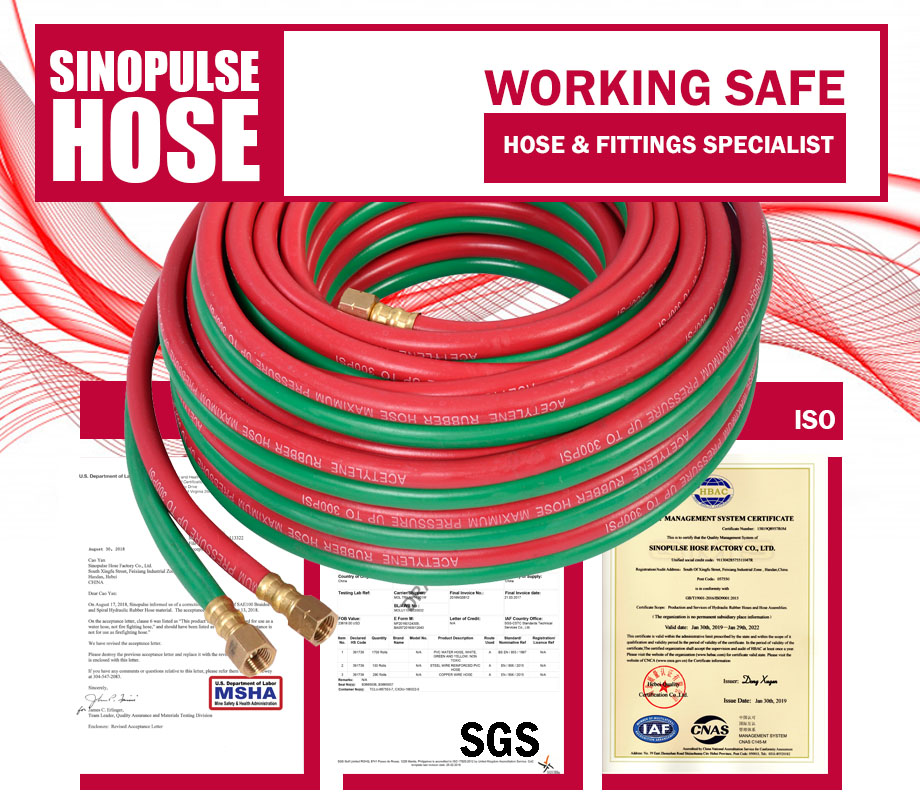

SINOPULSE FACTORY offers a variety of Industrial, Air - Water, oil hose, welding hose and Multipurpose Hose to handle any application. Our hoses are designed to perform in both high and low and pressures and are suitable for a variety of applications.

| Bagian No. | ID | OF | Tekanan Kerja | Tekanan Burst | dawa | |||

| inch | mm | mm | bar | psi | bar | psi | M | |

| OA300-03 | 3/16" | 4.8 | 12 | 20 | 300 | 60 | 900 | 100 |

| OA300-03D | 3/16"+3/16" | 4.8+4.8 | 12+12 | 20 | 300 | 60 | 900 | 100 |

| OA300-04 | 1/4“ | 6.4 | 13 | 20 | 300 | 60 | 900 | 100 |

| OA300-04D | 1/4"+1/4” | 6.4+6.4 | 13+13 | 20 | 300 | 60 | 900 | 100 |

| OA300-05 | 5/16" | 7.9 | 15 | 20 | 300 | 60 | 900 | 100 |

| OA300-05D | 5/16"+5/16" | 7.9+79 | 15+15 | 20 | 300 | 60 | 900 | 100 |

| OA300-06 | 3/8" | 9.5 | 17 | 20 | 300 | 60 | 900 | 100 |

| OA300-06D | 3/8"+3/8" | 9.5+9.5 | 17+17 | 20 | 300 | 60 | 900 | 100 |

Anti abrasion tutup alus

Cuaca lan tutup tahan ozon

Flexible, light weight, less distortionControl

Ora ana bahan daur ulang

resistance abrasion

Tes tekanan

Kekuwatan tensile

Monitoring vulkanisasi

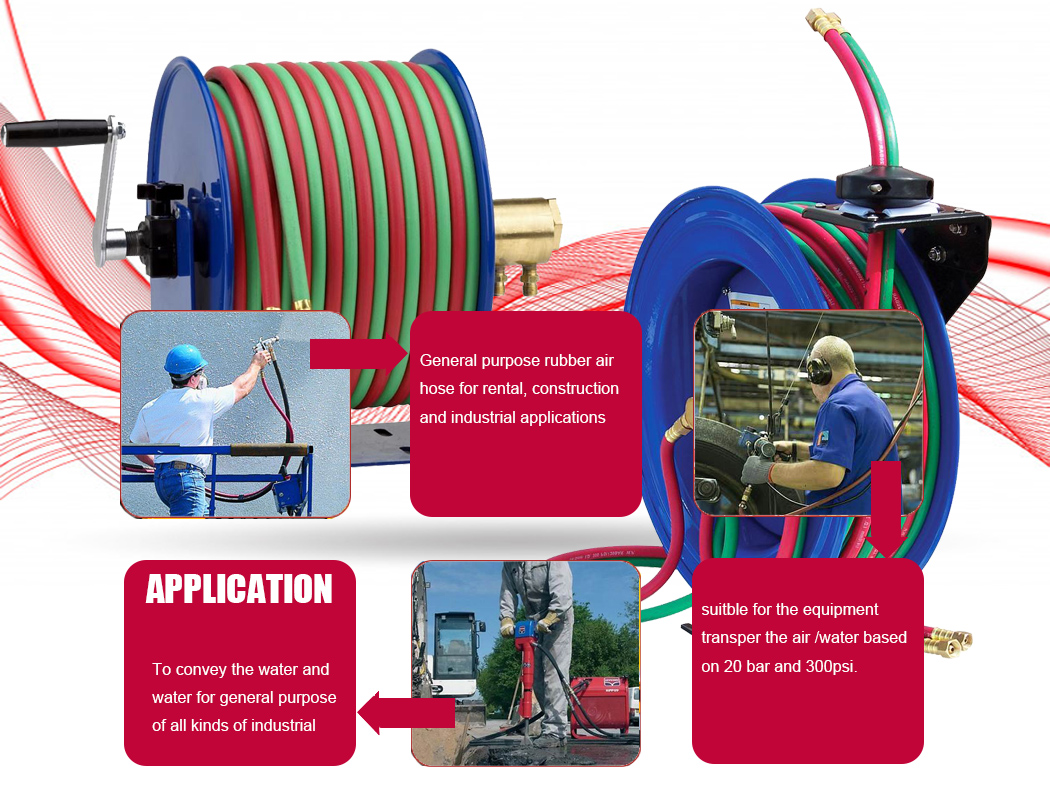

Mainly used for Welding equipment, Like welding, cutting and allied process, Specific welding hose cartering for oxygen, carbon dioxide, nitrogen, argon and fuel gases including acetylene, natural gas, methane and propane available upon request.

Kenapa Pilih Kita?

Pengalaman 1,15 taun lan produsen Sertifikat ISO 2015

2. Tes laboratorium menehi bahan mentah kualitas TOP

3. kertu tanggung jawab ngawasi saben langkah sak produksi

4. Institusi kontrol Kualitas sing ketat sawise produksi

5. Cepet, Ramah, pinter sales & sales profesional karo layanan jam kerja lengkap

6. Garansi layanan purna jual & garansi

7. Layanan merek OEM kasedhiya.

We strive to be the best fluid and power convey company in the world to make our products not only outperform industry standards, but also exceed our customers’ demanding expectations.

Whether you’re in construction, agriculture, mining, petroleum processing, foundry, shipyard, or quarry you can count on SINOPULSE FACTORY for all your needs.

We welcome kanggo kabeh pelanggan anyar lan klien njaluk sesambungan karo kita kanggo interaksi bisnis cilik mangsa lan sukses bebarengan. Produk kasebut bakal disedhiyakake ing saindenging jagad, kayata Italia, Jerman, Inggris, Spanyol.USA, Kanada, Brazil, Argentina, Panama, Peru, Chili, Vietnam, Indonesia, Australia ...

Kita duwe sawetara selang Industri gedhe ing pasar, sing bisa kepenak karo aplikasi tekanan sing beda.

Selang Air & Banyu

Selang Bahan Bakar Kab

Selang Beton Kab

Selang Kimia Kab

Selang Suction & Discharge

Selang Bensin

Selang Welding

Selang Sandblast Kab

Selang Truk Tank Kab

Selang Pangiriman Bahan

Selang Food Grade Kab

Selang uap

Selang Silikon Kab

Selang Rem

Selang A/C

Cracking the Code: How Working Pressure Dictates Optimal Oxy Acetylene Hose Diameters

SINOPULSE recognizes that the seamless operation of oxy-acetylene welding hoses hinges on the precise correlation between working pressure and hose diameter. In the high-stakes realm of oxy-fuel welding and cutting, this relationship isn't just technical—it's crucial for safety and efficiency.

For oxygen & acetylene hoses, smaller diameters, such as 3/16", are typically chosen for tasks demanding high gas velocity, like intricate jewelry welding or fine-detail metalwork. However, these narrow-bore hoses face increased internal friction. SINOPULSE engineers counter this by reinforcing these types of oxy-acetylene hoses with multiple layers of high-strength synthetic fibers. This design allows 3/16" hoses to maintain a working pressure of up to 20 bar, ensuring consistent gas flow despite the constricted space.

Conversely, larger oxy acetylene hose sizes, like 3/8", are engineered for heavy-duty applications in shipyards or construction sites. The wider bore reduces gas flow resistance, enabling higher volume delivery essential for large-scale metal cutting. SINOPULSE's oxy acetylene twin hoses in this size category feature thicker inner tubes and additional braided layers, boosting their working pressure capacity to 25 bar. This robust construction withstands the demands of continuous high-pressure gas flow without risk of expansion or leakage.

Safety remains at the forefront of SINOPULSE's design philosophy. Every oxy acetylene welding hose is built with a substantial safety margin, with a burst pressure rating of 60 bar, three times the maximum working pressure. This safeguards against sudden pressure surges caused by equipment malfunctions or rapid valve closures.

SINOPULSE offers a diverse range of hoses, each tailored to specific applications. Whether it’s a lightweight 3/16" hose for precision work or a heavy-duty 3/8" hose for industrial use, our oxygen & acetylene hoses ensure that the working pressure and diameter are perfectly matched, delivering reliable performance in every welding and cutting operation.

Unleashing Three Core Engineering Advantages of SINOPULSE Oxygen & Acetylene Hoses

As a trusted industrial hose manufacturer, SINOPULSE engineers oxygen & acetylene hoses with the precision demanded by heavy-duty welding and cutting operations. Our hoses stand out for three key engineering performance advantages, combining safety, durability, and operational efficiency across diverse industrial applications.

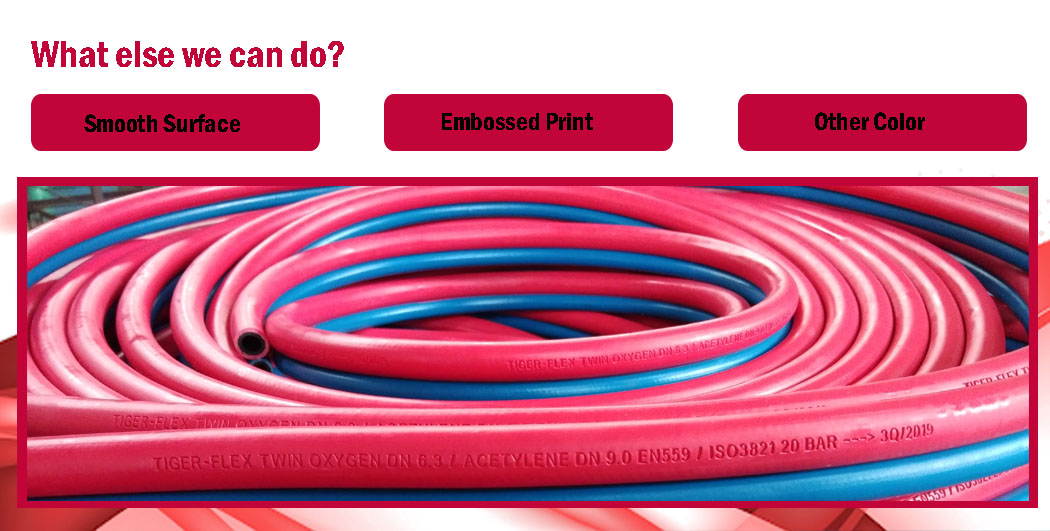

1. Dual-Chamber Safety Architecture for Explosion Prevention

SINOPULSE oxy acetylene twin hoses feature a proprietary dual-chamber design, separating oxygen and acetylene in distinct red-and-blue color-coded channels. This physical isolation eliminates the risk of explosive gas mixtures, a critical safety feature validated by burst pressure tests exceeding 60 bar—three times the maximum working pressure of 20 bar. The chambers are constructed from nitrile-butadiene rubber (NBR), resistant to oil, grease, and hydrocarbon degradation, ensuring long-term integrity even in high-temperature welding environments. This design meets international standards like NFPA 51, making it ideal for shipbuilding, construction, and metal fabrication.

2. Reinforced Multi-Layer Structure for Abrasion Resistance

Our oxy acetylene welding hoses incorporate a robust multi-layer construction: a smooth inner tube for low-flow resistance, a high-tensile synthetic fiber braid for pressure reinforcement, and an outer cover of chloroprene rubber. This design delivers exceptional abrasion resistance, with lab tests showing wear rates as low as 120 mm³ under ASTM D4060 standards. The outer layer resists sparks, flames, and mechanical impacts, while the braided layer maintains hose shape under pressures up to 25 bar. This makes SINOPULSE hoses suitable for rugged job sites where traditional hoses might crack or leak.

3. Versatile Sizing for Precision Flow Control

SINOPULSE offers a comprehensive range of oxy acetylene hose sizes (3/16" to 3/8") to match specific operational needs. Smaller diameters like 3/16" are optimized for precision welding, with reinforced walls to counteract pressure drop (maintaining 17 bar at high flow), while 3/8" hoses excel in heavy-duty cutting, handling higher gas volumes with minimal resistance. Each size undergoes temperature cycling tests (-32°C to 80°C) to ensure flexibility in extreme conditions, and anti-static additives in select models dissipate electrical charges, reducing ignition risks in flammable environments.

By integrating safety, durability, and adaptability, SINOPULSE types of oxy-acetylene hoses redefine industry standards. Whether for fine-scale metalworking or large-scale construction, our hoses deliver reliable performance that engineers and operators can trust.