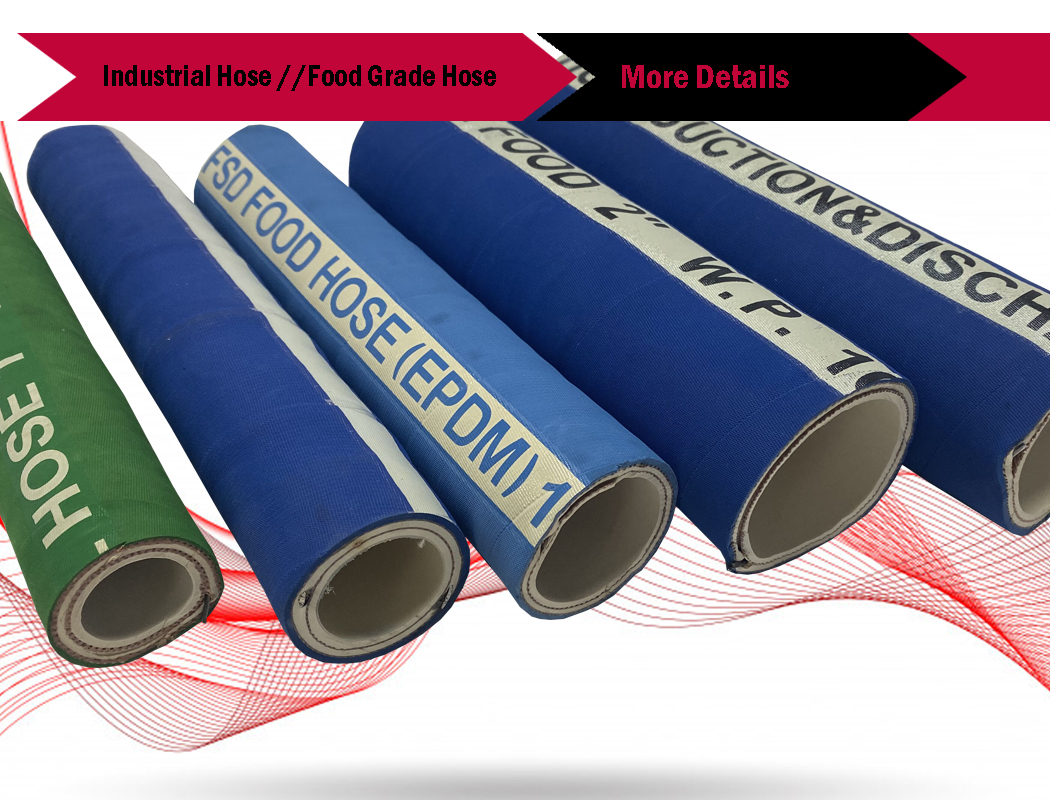

FDA 認定の食品グレードのゴムホースは、さまざまな業界で広く使用されています。固形、液体、その他の食品の排出と吸引に広く使用されています。食品グレードのゴムホースは、さまざまなゴム化合物から製造され、高張力合成繊維、ワイヤー、またはその両方の組み合わせで補強されています。

食品グレードのゴムチューブは、食品加工工場の厳しい条件を満たすために製造されています。手荒な取り扱いや高温の状況にも耐えることができます。高品質の食品グレードのホースは、高圧供給を維持できます。

| 部品番号 | ID | の | 作動圧力 | 破裂圧力 | 層 | |||

| インチ | んん | んん | バー | サイ | バー | サイ | プライ | |

| FD300-04 | 1/4" | 6.4 | 14.0 | 20 | 300 | 60 | 900 | 1 |

| FD300-05 | 5/16" | 7.9 | 16.0 | 20 | 300 | 60 | 900 | 1 |

| FD300-06 | 3/8" | 10.5 | 18.0 | 20 | 300 | 60 | 900 | 1 |

| FD300-08 | 1/2" | 12.7 | 22.0 | 20 | 300 | 60 | 900 | 1 |

| FD300-10 | 5/8" | 15.9 | 26.0 | 20 | 300 | 60 | 900 | 1 |

| FD300-12 | 3/4" | 19.1 | 29.0 | 20 | 300 | 60 | 900 | 1 |

| FD300-16 | 1" | 25.4 | 37.0 | 20 | 300 | 60 | 900 | 2 |

| FD300-20 | 1-1/4" | 31.8 | 45.8 | 20 | 300 | 60 | 900 | 4 |

| FD300-24 | 1-1/2" | 38.2 | 52.6 | 20 | 300 | 60 | 900 | 4 |

| FD300-32 | 2" | 50.8 | 65.6 | 20 | 300 | 60 | 900 | 4 |

| FD300-40 | 2-1/2" | 64.0 | 80.2 | 20 | 300 | 60 | 900 | 6 |

| FD300-48 | 3" | 76.0 | 93.4 | 20 | 300 | 60 | 900 | 6 |

| FD300-64 | 4" | 102.0 | 120.6 | 20 | 300 | 60 | 900 | 6 |

| FD300-80 | 6" | 152.0 | 170.6 | 20 | 300 | 60 | 900 | 6 |

食品グレードチューブ

耐候性と耐摩耗性に優れたカバー

多種多様な食品を取り扱っています

滑らかなカバーと波型カバーの両方が利用可能

当社工場ではリサイクル材料を使用せず、生産前に圧力テスト、引張強度テストを行い、生産後に加硫のモニタリングを行います。

1.プロセス転送、洗浄ステーション、バルク食品処理。

2.食品グレードのホースは、ワイン、ビール、牛乳、サイダー、フルーツジュース、アルコール度数 96% までのその他の液体食品の吸引と排出に適しており、飲料製造、ワイナリー、醸造所、蒸留所でのタンク移送用に特別に設計されています。

当社を選ぶ理由

1.15年の経験とISO 2015認証メーカー

2. 実験室テストにより最高品質の原材料が提供されます

3. 責任カードは生産中のすべてのステップを監督します

4. 生産後の厳格な品質管理機関

5. 迅速でフレンドリー、知識豊富なセールスおよびセールスプロフェッショナル、営業時間延長サービス

6.アフターサービス保証

7. OEMブランドサービスもご利用いただけます。

We strive to be the best fluid and power convey company in the world to make our products not only outperform industry standards, but also exceed our customers’ demanding expectations.

SINOPULSE は、新規および既存のお客様を歓迎します。今後の小規模ビジネス交流と相互成功のために、当社にご連絡ください。製品は、イタリア、ドイツ、英国、スペイン、米国、カナダ、ブラジル、アルゼンチン、パナマ、ペルー、チリ、ベトナム、インドネシア、オーストラリアなど、世界中に供給されます。当社は、活気ある展望を持ち、近い将来に世界中に流通されると確信しています。

当社は、さまざまな圧力用途に対応できる幅広い産業用ホースを市場に提供しています。

エア&ウォーターホース

燃料油ホース

コンクリートホース

化学ホース

吸引・排出ホース

ガソリンホース

溶接ホース

サンドブラストホース

タンクローリーホース

材料搬送ホース

食品グレードホース

蒸気ホース

シリコンホース

ブレーキホース

エアコンホース

Decoding the Core Materials Hygienic Design Principles of Food Grade Hoses

SINOPULSE engineers food-grade hoses with a meticulous focus on material purity and hygienic design, ensuring safe and compliant transfer of food and beverage products. The selection of core materials and the architecture of these hoses play a pivotal role in meeting strict industry standards while delivering reliable performance for food transfer hose applications.

1. FDA-Compliant Elastomeric Materials: The Foundation of Purity

SINOPULSE food grade hoses are built with inner tubes crafted from premium elastomers like ethylene-propylene-diene-monomer (EPDM) or nitrile-butadiene rubber (NBR), both rigorously certified to FDA 21 CFR 177.2600 for direct food contact. EPDM, with its non-polar molecular structure, excels in resisting aqueous solutions, making it ideal for transferring water-based foods like juices, dairy, and sauces. NBR, fortified with food-safe additives, offers superior resistance to oils and fats, critical for conveying edible oils, margarine, or bakery products. These materials are free from phthalates, heavy metals, and other contaminants, ensuring zero migration of harmful substances into the food stream—an essential feature for multipurpose hose 20 bar applications requiring both versatility and safety.

2. Smooth-Bore Design for Hygienic Flow

The inner surface of SINOPULSE food transfer hoses is engineered to a surface roughness of ≤0.8μm (Ra), minimizing product residue buildup and facilitating easy cleaning. This smooth bore reduces the risk of bacterial growth or cross-contamination, a critical advantage in sensitive processes like infant formula production or pharmaceutical-grade syrup transfer. Unlike conventional hoses with textured interiors, our seamless design eliminates crevices where particulates could lodge, supporting compliance with stringent cleaning protocols such as Clean-in-Place (CIP) and Sterilize-in-Place (SIP).

3. Reinforcement Layers for Pressure Stability

To meet the demands of high-pressure systems—including 20 bar hose and 20 bar air hose applications—SINOPULSE integrates spiral-wound stainless steel wire or high-tensile polyester braids into the hose structure. These reinforcement layers distribute internal pressure evenly, enabling working pressures up to 20 bar (300 PSI) while maintaining flexibility for easy installation. The stainless steel option, in particular, adds corrosion resistance, making it suitable for harsh cleaning agents used in food processing facilities.

4. Outer Cover Protection Without Compromise

The outer layer of SINOPULSE food grade hoses is constructed from abrasion-resistant, non-toxic synthetic rubber or thermoplastic elastomers (TPE), designed to withstand physical abuse in industrial environments without compromising hygiene. UV-resistant formulations are available for outdoor use, preventing material degradation from sunlight exposure, while anti-static additives in select models eliminate electrostatic hazards when handling flammable food products like alcohol or spirits.

Certifications Beyond Compliance

In addition to FDA approval, SINOPULSE hoses undergo rigorous testing to meet NSF 51 (for food contact materials) and USP Class VI (for pharmaceutical applications), ensuring suitability for even the most sensitive food and beverage transfer tasks. Each hose is traceable through its material supply chain, guaranteeing no recycled materials are used—a critical factor for brands prioritizing product integrity.

Whether transferring delicate dairy products, viscous sauces, or high-alcohol beverages, SINOPULSE food grade hoses combine advanced material science with hygienic engineering to deliver safe, efficient, and compliant solutions. As a trusted industrial hose manufacturer, we understand that in food processing, purity is not just a feature—it’s a necessity.

Cleanliness Verification and Maintenance Protocols for Food Grade Hoses

As a reputable industrial hose manufacturer, SINOPULSE recognizes that the safety and integrity of food products rely not only on the quality of food-grade hoses but also on proper cleaning and maintenance. Our food transfer hoses are engineered to meet strict hygiene standards, and following the right verification and maintenance practices ensures their long-term performance and compliance with food safety regulations.

1. Cleaning Verification: Ensuring Purity with Rigorous Testing

SINOPULSE food grade hoses are designed to support comprehensive cleaning verification processes. For hoses used in high-risk applications, such as dairy or infant food production, we recommend conducting residue tests after each cleaning cycle. A simple visual inspection for any visible residue is the first step. For more precise verification, swab tests can be performed on the inner surface of the hose. These swabs are then analyzed for microbial presence, ensuring that the hose is free from bacteria, yeasts, or molds.

In facilities using Clean-in-Place (CIP) systems, SINOPULSE 20 bar hose and multipurpose hose 20 bar models are designed to withstand the high-pressure cleaning solutions typically used. The smooth inner bore (≤0.8μm Ra) of our hoses facilitates efficient cleaning, reducing the risk of residue buildup. To verify the effectiveness of CIP, water conductivity tests can be conducted post-cleaning. A significant drop in conductivity indicates the removal of contaminants, confirming the hose’s cleanliness.

2. Maintenance Protocols: Prolonging Hose Lifespan

Regular maintenance is key to extending the lifespan of SINOPULSE food-grade hoses. Visual inspections should be carried out frequently to check for signs of wear, such as cracks, bulges, or abrasions on the outer cover. For hoses used under high-pressure conditions, like 20 bar air hose or 20 bar hose applications, pressure testing should be performed annually. This ensures that the hose can still handle the required working pressure of 20 bar (300 PSI) without compromising safety.

When not in use, food transfer hoses should be stored in a clean, dry environment away from direct sunlight. SINOPULSE hoses with UV-resistant outer covers are suitable for outdoor storage, but indoor storage is still recommended for maximum protection. Additionally, hoses should be coiled loosely to prevent kinking, which can damage the internal reinforcement layers and affect pressure-handling capabilities.

3. Record-Keeping for Traceability

SINOPULSE emphasizes the importance of maintaining detailed records of all cleaning and maintenance activities. This includes the date of cleaning, the type of cleaning agent used, and the results of any verification tests. For an industrial hose manufacturer, compliance and customer assurance, these records provide traceability, demonstrating that the hoses are being properly maintained and are safe for food transfer.

By following SINOPULSE’s cleanliness verification and maintenance protocols, food processing facilities can ensure the continued safety and reliability of their food-grade hoses, safeguarding both their products and their brand reputation.